I also sanded into the weave around the insert. Thought the seal coat would tame the fibers, but they protruded enough, that I had to scrape, before laying cloth down.

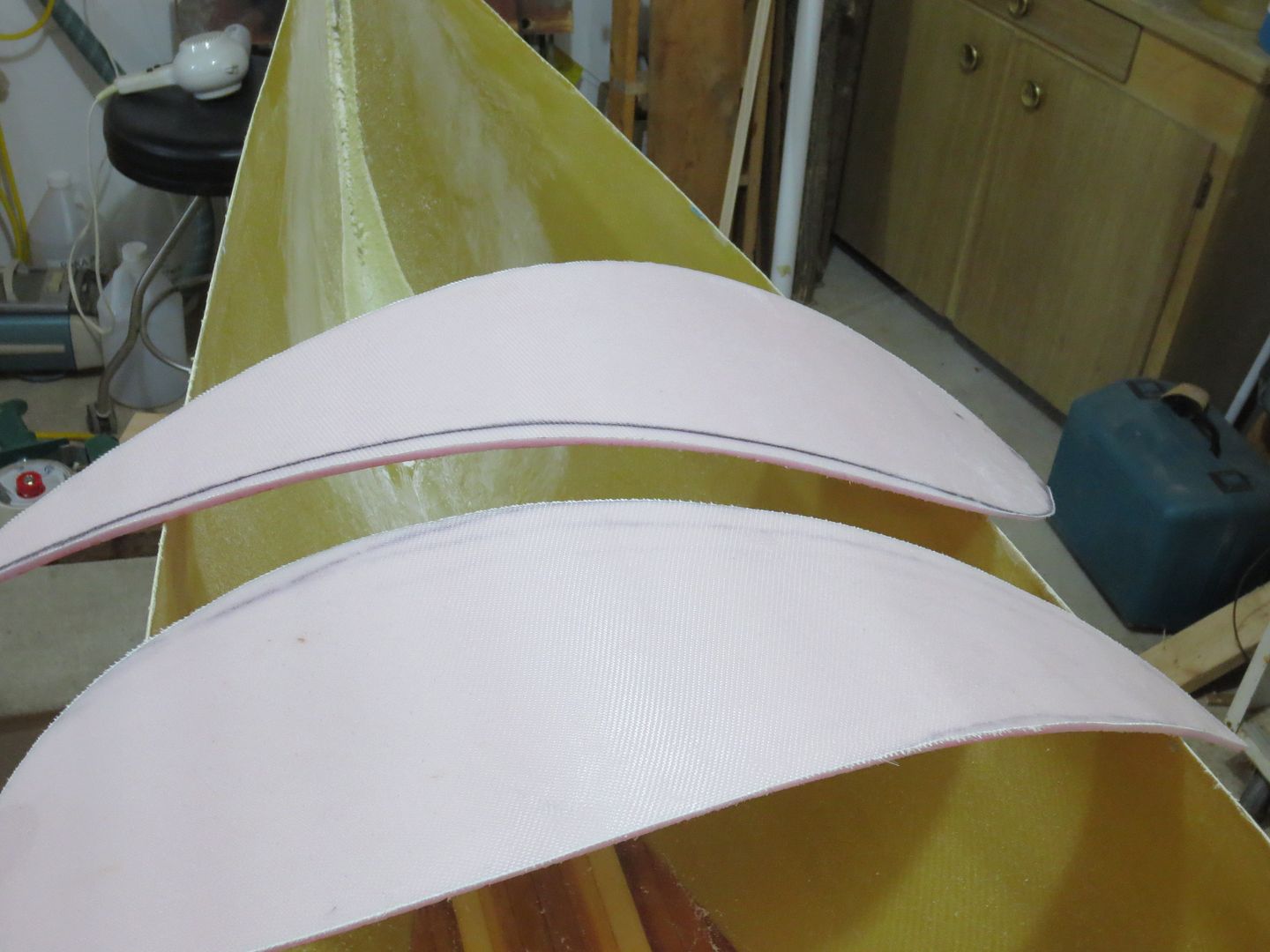

The batten and clips were just to hold the shear shape, while the epoxy set.

The wrinkles were fine after I scraped them smooth. They just made extra work.

With one layer of 8.9 oz Woven Kevlar. Two full layers of 6 oz E-glass, and two near full layers of 6 oz S-glass plus the 1/8" cedar insert. I'm happy with the stiffness.

I realize vacuum bagging, or infusion, would have save a lot of resin ! I need to advance my method.

I will weigh both hulls before installing trim.

Jim

The batten and clips were just to hold the shear shape, while the epoxy set.

The wrinkles were fine after I scraped them smooth. They just made extra work.

With one layer of 8.9 oz Woven Kevlar. Two full layers of 6 oz E-glass, and two near full layers of 6 oz S-glass plus the 1/8" cedar insert. I'm happy with the stiffness.

I realize vacuum bagging, or infusion, would have save a lot of resin ! I need to advance my method.

I will weigh both hulls before installing trim.

Jim

Last edited: