Pulled the forms out of Pearl, and flipped her over. Bead and Cove is GREAT ! 10 minutes of scraping, and now to sand, Love anything that saves sanding time, and B&C does that !

Bought out the old spring scale.

The Kevlar, weights 15# and Pearl at 30#.

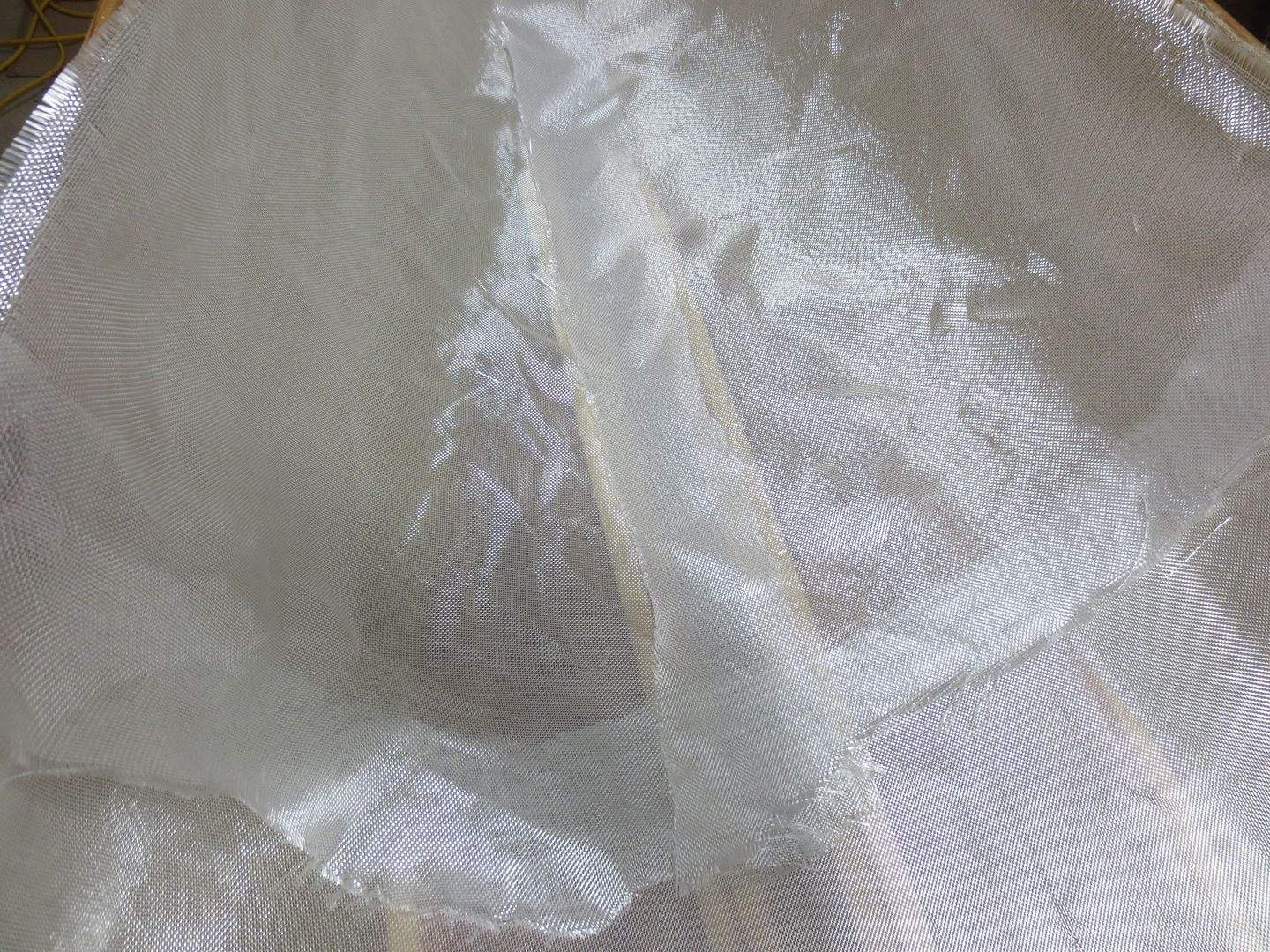

The Kevlar will get an insert, and more glass, but that is quite a weight difference !

Jim

Bought out the old spring scale.

The Kevlar, weights 15# and Pearl at 30#.

The Kevlar will get an insert, and more glass, but that is quite a weight difference !

Jim