Lots of talented woodworkers are here on the forum. Hoping folks will use this thread to post some of their scrap wood project ideas. I'm looking to pass the winter by using up my pile of hardwood cutoffs.

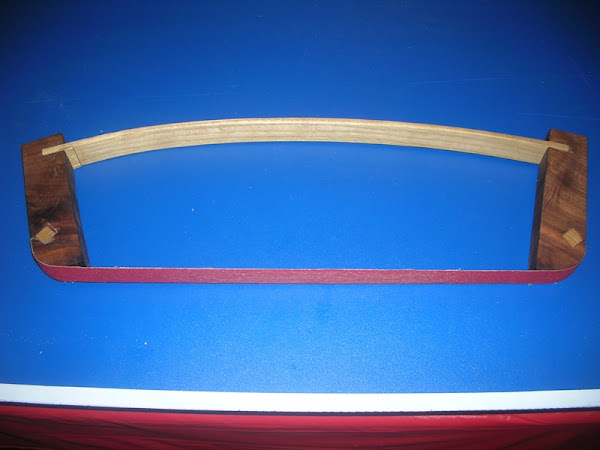

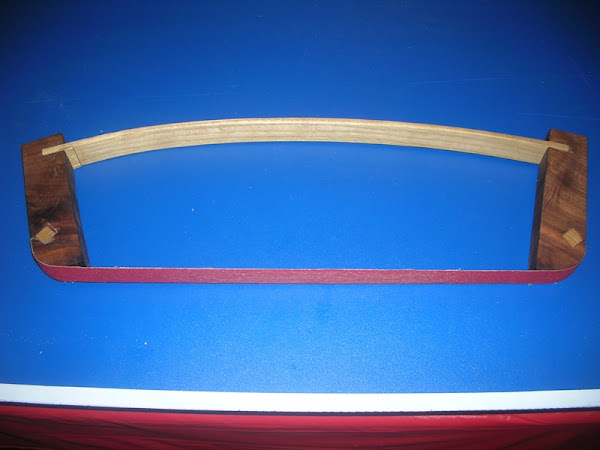

Just finished making a sanding tool modeled after the "MacFarlane Bow Sander". Mine has walnut for the handles with a flexible strip of sassafras for the crosspiece. Some smaller sassafras pieces were shaped into squarish dowels to hold a standard 1" x 30" belt sander strip in place. Here are the pieces laid out for a visual and then assembled under tension.

Also been making some wooden camping tools for my boys. Figured they might need all their fingers in the future so made some dull wooden versions to play with and safely practice for the real thing. Made an axe, a bucksaw, belt knife, crooked knife, awl, chisel and a mini firesteel rod.

The wooden axe head and fake blade for the bucksaw were stained using a natural mixture of steel nails, vinegar and black tea found on this tutorial here. Seemed like a neat way to naturally darken wood.

What have you made or plan to make from your scrap pile?

Just finished making a sanding tool modeled after the "MacFarlane Bow Sander". Mine has walnut for the handles with a flexible strip of sassafras for the crosspiece. Some smaller sassafras pieces were shaped into squarish dowels to hold a standard 1" x 30" belt sander strip in place. Here are the pieces laid out for a visual and then assembled under tension.

Also been making some wooden camping tools for my boys. Figured they might need all their fingers in the future so made some dull wooden versions to play with and safely practice for the real thing. Made an axe, a bucksaw, belt knife, crooked knife, awl, chisel and a mini firesteel rod.

The wooden axe head and fake blade for the bucksaw were stained using a natural mixture of steel nails, vinegar and black tea found on this tutorial here. Seemed like a neat way to naturally darken wood.

What have you made or plan to make from your scrap pile?

Last edited: