Jim, as you can imagine I am sorting through multiple options for laying the fiberglass. The brush and squeegee are what I am most familiar with based on what I have watched and learned thus far.....like the canoe craft video that cruiser shared. I am willing to try the cigar roller application, however I would imagine that a squeegee would create a more positive contact with the fiberglass to hull with the wet out. Not sure...see what I mean. So many ways so few days!

-

Happy National Bugs Bunny Day (1938)!❓⬆️👨🏼⚕️

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My First Canoe Build

- Thread starter dcloots

- Start date

Count me as one of the "others"...I always apply a seal coat before the glass and wet out. I mostly use RAKA resin, and IIRC, there was a statement that you'll still get a chemical bond as long as you're within 72 hours from the last application. FWIW, I've never had a delamination with epoxy resin, and I've damaged quite a few hulls.

After my seal coat, I lightly sand the hull to knock off any dust burrs.

Just before laying on the cloth, I also sand my hands with some 220 grit, I always have cuts and snags on my hands and this helps prevent pulls on the cloth as I'm smoothing things out.

And yes, if I'm using an extra 1/2 layer, I wet that out at the same time as the full layer. I put the 1/2 layer under the full layer, others put the 1/2 layer on the outside.

Like Alan, I pour my mixed resin directly on the flatter parts of the hull and work it around with a squeegee. And before everything is kicked, I squeegee again to remove any entrained air and force the glass down as close as possible to the wood. I get better strength and a more clear lamination that way.

If I was using a roller, I would keep the filled tray on the concrete floor to help keep the resin cool.

Also, I do not trust any metering pumps, I've seen much disparity between what I thought I measured and the actual quantity. A small error times 20 pumps quickly becomes significant. For larger quantities, I prefer graduated paint cups,. Be sure to thoroughly scrape the sides of any cups, any leftover resin or hardener will add to ratio disparities. For small quantities, I used graduated syringes, I think each one holds a maximum of 2 oz.

That's al I can think of for now...wait! I don't remember if you've already purchased your resin, but if not, buy a SLOW hardener, it will keep your blood pressure lower.

I will research US Composites tonight for the chemical bonding time requirement. I have chosen US Composites for my epoxy. It was the most affordable and the reviews were decent. If I can not find what I am looking for I will call them directly tomorrow. I think I am leaning towards wetting out the hull prior to the glass. I would most likely use a cigar roller to do this and then squeegee after. I guess I will know when the time comes and share with you all how I ended up doing it on the next video.....Very perplexed as the multiple methods all seem to make sense to me. Stripperguy, after the wet out coat prior to glass, how many hours do you let pass before lightly sanding and laying the glass and wetting that in?

Last edited:

I did.

She is a beauty Alsg. I truly admire your work. Beautiful boat!!!

She is a beauty Alsg. I truly admire your work. Beautiful boat!!!

Yours will be beautiful, too, I promise!

Jim, as you can imagine I am sorting through multiple options for laying the fiberglass. The brush and squeegee are what I am most familiar with based on what I have watched and learned thus far.....like the canoe craft video that cruiser shared. I am willing to try the cigar roller application, however I would imagine that a squeegee would create a more positive contact with the fiberglass to hull with the wet out. Not sure...see what I mean. So many ways so few days!

Regardless of how you put the resin on, your last step will be to squeegee off the excess (this will push the cloth in as well ... you don't really need it at the start), so it really comes down to what feels "good or natural" to you, some folks like squeegee, some brushes, some rollers, i like to pour it on and distribute with a roller, just what i got used to in the beginning.

The thing that gets important, is to keep going back and checking, once the epoxy starts to thicken in an area, it is important to get there and squeegee it, this pushes it in tight and removes the excess epoxy. Also, don't just leave the epoxy and walk away, you need to keep checking on it for runs/bubbles, almost like babysitting a 2 year old .... don't let down your guard.

Brian

I've seen similar time frames for the "mechanical vs chemical" bond thing as Stripperguy. System three gives a 72 hour period as well, and I suspect most quality epoxies are the same. I never rush my fill coats as a result, I wait till the surface is tack free before applying another coat, and if it happens to be an overnight wait, I don't worry. It has taken me up to three days to complete fill coats, no adverse effects resulted. People get very worried about the fiberglassing process, when I think it is really one of the easiest and quickest steps in the whole business.

I wait a full day between the seal coat and laying out the cloth

I want to be sure there is no tackiness before laying on the cloth

if tacky it’s nearly impossible to smooth out any wrinkles

I know some guys lay their cloth on a just epoxied surface but that’s always with team of helpers

I’m generally working alone so a dry clean hull is essential

And I know Jim and even a buddy of mine prefer those cigar rollers but for me I prefer a full size roller, it holds more resin

I want to be sure there is no tackiness before laying on the cloth

if tacky it’s nearly impossible to smooth out any wrinkles

I know some guys lay their cloth on a just epoxied surface but that’s always with team of helpers

I’m generally working alone so a dry clean hull is essential

And I know Jim and even a buddy of mine prefer those cigar rollers but for me I prefer a full size roller, it holds more resin

If you check with System Three, They will advise to add fill coats, while the previous coat is still tacky !

I used to do like Mem and Stripperguy, but after I learned from System Three, I find it really improved clearity, and reduced runs in the epoxy.

The drawback, is I'm up in the night putting that last coat on ! The wet out coat, and two or three fill coats in one day.

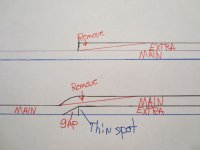

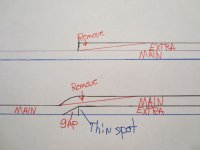

I always add the extra layer on the bottom, on top of the main layer. Below is a drawing of my reasoning. The top example makes sense to me.When it comes time to sand and feather the edges.

Two Bias trips covering the ends. This gives me 4 layers of cloth, where the hull gets the most wear.

I used to do like Mem and Stripperguy, but after I learned from System Three, I find it really improved clearity, and reduced runs in the epoxy.

The drawback, is I'm up in the night putting that last coat on ! The wet out coat, and two or three fill coats in one day.

I always add the extra layer on the bottom, on top of the main layer. Below is a drawing of my reasoning. The top example makes sense to me.When it comes time to sand and feather the edges.

Two Bias trips covering the ends. This gives me 4 layers of cloth, where the hull gets the most wear.

Last edited:

Very perplexed as the multiple methods all seem to make sense to me.

I remember that feeling from my first build. All I wanted was to be told "do it this one way" but the more I looked the more options/opinions I found. After building quite a few canoes I can say don't get hung up on it (any of it). They're all going to work. None of them are going to turn your canoe into a lemon. If you keep building you'd find a real freedom in this but at first it's frustrating.

Builders can be particular and adamant about their own method but it's important to step back and see they're all achieving the same result.

Alan

I was thinking the same thing Jim noted about epoxy timing (actually about the order of layers as well) ... most epoxies I have read up on suggest subsequent coats at the tacky stage which is in the range of ~3 hours with a clear hardener. There is a fair range though and some are fairly extended as Mem suggests.... CHECK with your epoxy manufacturer and don't assume ... you can make too big a mess if you guess or assume incorrectly, it's a simple phone call or email.

Jim you have posted that pic before and it makes it clear, to me at least, that adding that layer under a covering layer will indeed create a weak spot once it gets sanded or leveled. I suspect that even if you leave it, the sharp turn/corner won't be as strong as most structures like that don't like turns from a strength PoV.

Brian

Jim you have posted that pic before and it makes it clear, to me at least, that adding that layer under a covering layer will indeed create a weak spot once it gets sanded or leveled. I suspect that even if you leave it, the sharp turn/corner won't be as strong as most structures like that don't like turns from a strength PoV.

Brian

Beings you are just about ready to glass, I'll offer a few tips, I've learned that helped me over the years.

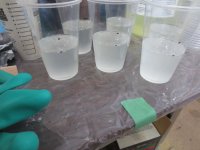

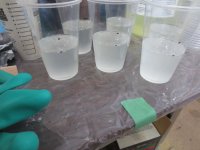

I purchase clear smooth sided 16 oz cups, usually from Walmart.

I then measure and mark a bunch, with a Sharpy. (I'm Cheap). I used to used waxed cups from System Three, but always worried about abrading the cup with my mixing sticks. The reason I went to plastic.

Back to the cups ! After they are marked, I fill as many as I think I will use in one session, with RESIN, in my case 6 oz each.

When it comes time for another cup, all I need do is add Hardener, up to the 9 oz mark, and stir.. This saves me time, when I'm working alone. Things get Hectic sometimes !

Caution ! Don't leave resin filled cups for a long period of time ! Two days at the max. Some resins will soften the plastic and leak !

I use one pump on my Hardener jug, I always just pour from the Resin jug. This prevents me from mixing them up in I'm in a hurry.

I purchase clear smooth sided 16 oz cups, usually from Walmart.

I then measure and mark a bunch, with a Sharpy. (I'm Cheap). I used to used waxed cups from System Three, but always worried about abrading the cup with my mixing sticks. The reason I went to plastic.

Back to the cups ! After they are marked, I fill as many as I think I will use in one session, with RESIN, in my case 6 oz each.

When it comes time for another cup, all I need do is add Hardener, up to the 9 oz mark, and stir.. This saves me time, when I'm working alone. Things get Hectic sometimes !

Caution ! Don't leave resin filled cups for a long period of time ! Two days at the max. Some resins will soften the plastic and leak !

I use one pump on my Hardener jug, I always just pour from the Resin jug. This prevents me from mixing them up in I'm in a hurry.

I have recently emailed US Composites inquiring about how much time should elapse between fill coats. Hope to hear something soon.

Digesting all of this great information has been interesting and fun to say the least. There are clearly so many options, applications and methods to utilize. The methods that make most sense to me will be the application of the secondary bottom layer on top of the main layer. I fully intend to do this. I also intend to prefill the graduated cups(premarked and already on hand) with resin to the 3 oz mark for 4 oz batches. I can see the full benefit of doing this in advance. I believe I am now leaning towards using a decent nap roller that holds enough resin to wet out the glass. I will then squeegee after the roll-on process to press the glass tight to the hull without removing too much resin from the glass. Ted Moore demonstrated this perfectly at a low angle. Roll, then squeegee. I think that will be the plan. I will wet out half of the canoe than go back and squeegee. Then continue wetting out the other half trying to maintain the "wet edge".

Digesting all of this great information has been interesting and fun to say the least. There are clearly so many options, applications and methods to utilize. The methods that make most sense to me will be the application of the secondary bottom layer on top of the main layer. I fully intend to do this. I also intend to prefill the graduated cups(premarked and already on hand) with resin to the 3 oz mark for 4 oz batches. I can see the full benefit of doing this in advance. I believe I am now leaning towards using a decent nap roller that holds enough resin to wet out the glass. I will then squeegee after the roll-on process to press the glass tight to the hull without removing too much resin from the glass. Ted Moore demonstrated this perfectly at a low angle. Roll, then squeegee. I think that will be the plan. I will wet out half of the canoe than go back and squeegee. Then continue wetting out the other half trying to maintain the "wet edge".

I think you'll want more than 4oz batches of epoxy for wetting out the hull. At 4oz it's gonna take a lot of batches to do the hull and you'll spend a couple minutes mixing each one, which will eat into the working time you have on the hull.

I'd usually mix up one or two 20oz batches that I'd pour directly only the hull for squeegee work and then 10-12oz batches when I switched to the roller. My goal was the get the resin on the hull as quickly as possible. Apply fast and come back later to clean it up before it kicks.

I don't quite follow Jim's diagram of multiple layers of cloth. Isn't the spot that's labeled "thin spot" actually thicker than the diagram showing the second layer on top?

Alan

I'd usually mix up one or two 20oz batches that I'd pour directly only the hull for squeegee work and then 10-12oz batches when I switched to the roller. My goal was the get the resin on the hull as quickly as possible. Apply fast and come back later to clean it up before it kicks.

I don't quite follow Jim's diagram of multiple layers of cloth. Isn't the spot that's labeled "thin spot" actually thicker than the diagram showing the second layer on top?

Alan

You should be aware that using a thick nap roller, or any roller, is a good way to add air bubbles into the epoxy. I have never wet out using a roller, and it may well be a good way to do it, but you'll have to be careful. Keep a heat gun, hair dryer or a torch nearby and run it across the surface before it kicks to get air bubbles to pop.

Also, when you do your second football layer you might want to check out how Nick Schade does it. He lays down masking tape where he wants to have the glass end, then glasses over the tape. When that layer hardens, but is still green, he carefully runs a razor along the tape edge and ends up with a really clean transition. I did this around the coaming of my last build, but forgot to try it on the 2nd layer of the hull. It's very slick and will save you a bunch of time trying to fair that layer with a scraper.

Mark

Also, when you do your second football layer you might want to check out how Nick Schade does it. He lays down masking tape where he wants to have the glass end, then glasses over the tape. When that layer hardens, but is still green, he carefully runs a razor along the tape edge and ends up with a really clean transition. I did this around the coaming of my last build, but forgot to try it on the 2nd layer of the hull. It's very slick and will save you a bunch of time trying to fair that layer with a scraper.

Mark

Never watched Nich Schade before. https://www.youtube.com/watch?v=qsupx-IXOzU

I've always just put the football under the main layer and wet them both out at the same time. Seems to work pretty good.

As Alan mentions, it’s important to get the resin on the hull as quickly as possible

Remember it takes some time for the resin to soak through the cloth

I generally pour on up to 18 oz of resin and spread it out quickly with a squeegee

I don’t get too hung up in perfect saturation until the resin has been on the glass for a bit

It can’t be rushed no matter how fast you squeegee or roll

And lastly, use a foam roller sleeve not some fuzzy paint roller otherwise you’ll be picking fuzz out of your resin forever

Remember it takes some time for the resin to soak through the cloth

I generally pour on up to 18 oz of resin and spread it out quickly with a squeegee

I don’t get too hung up in perfect saturation until the resin has been on the glass for a bit

It can’t be rushed no matter how fast you squeegee or roll

And lastly, use a foam roller sleeve not some fuzzy paint roller otherwise you’ll be picking fuzz out of your resin forever

Never watched Nich Schade before. https://www.youtube.com/watch?v=qsupx-IXOzU

Nick has lots of good videos, even though he's using all those skills to build kayaks! ha. Here's a video of his that catches what I was talking about. I think this link will take you to what I was trying to describe above.

Mark

It's incredible how every builder has their own method, and we all seem to come out with great boats. You will too !

The fun lies in making the choices that work for you. As they did for the rest of us !

Again, Good Luck !

Jim

The fun lies in making the choices that work for you. As they did for the rest of us !

Again, Good Luck !

Jim

Nick has lots of good videos, even though he's using all those skills to build kayaks! ha. Here's a video of his that catches what I was talking about. I think this link will take you to what I was trying to describe above.

Mark

It didn't. Go to 4:25 and watch from there.

Mark

Similar threads

- Replies

- 12

- Views

- 972

- Replies

- 73

- Views

- 6K