Hey there everyone,

It's been a while since posting here. Life is crazy sometimes. Stuff happens you know?

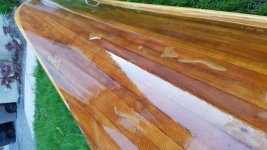

Anyways, Some of you will remember me documenting my Hiawatha build here a while ago. I just pulled the canoe out of the garage and dusted it off and found this mess! Wow. I did notice some signs of this last year, but it wasn't this bad. I have done some quick research into the best way to repair it but there seem to be differing opinions. I trust that some of you have had to face this kind of thing in the past and had some success in repairs. Any suggestions?

I'd like to document the repairs too. Maybe it can help someone else.

Thanks folks,

Momentum

It's been a while since posting here. Life is crazy sometimes. Stuff happens you know?

Anyways, Some of you will remember me documenting my Hiawatha build here a while ago. I just pulled the canoe out of the garage and dusted it off and found this mess! Wow. I did notice some signs of this last year, but it wasn't this bad. I have done some quick research into the best way to repair it but there seem to be differing opinions. I trust that some of you have had to face this kind of thing in the past and had some success in repairs. Any suggestions?

I'd like to document the repairs too. Maybe it can help someone else.

Thanks folks,

Momentum