Here we go again! Hoping to start building this week. I'm donating labor on this one to the local nature center to be raffled/auctioned at their annual fund raiser in the spring. Which means I need to take other people into consideration when figuring out what to build. Not many serious paddlers around here with Alumicraft and Grumman being the standard canoes with the odd exotic layup (Royalex). So I'm thinking pretty flat bottomed and fairly wide for plenty of stability but a little rocker for maneuverability and some tumblehome to help out the stern paddler. This will be my first boat with standard wood seats, thwarts, and gunwales with a bit of a "weight be danged" mentality, though I will be working to shave weight where I can. Since the west fork of the Des Moines river is our local waterway, which the nature center is also trying to get turned into a state approved water trail, the canoes name will be, "Des Moines."

There will be some more tweaking but the design is getting close. 17'x35" max, 33" WL, 33.5" gunwale

Desmoines_v4_Linesplan by Alan Gage, on Flickr

Desmoines_v4_Linesplan by Alan Gage, on Flickr

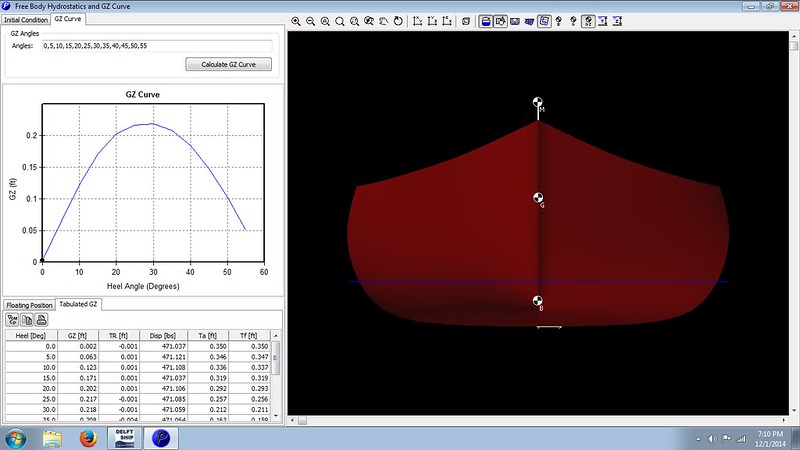

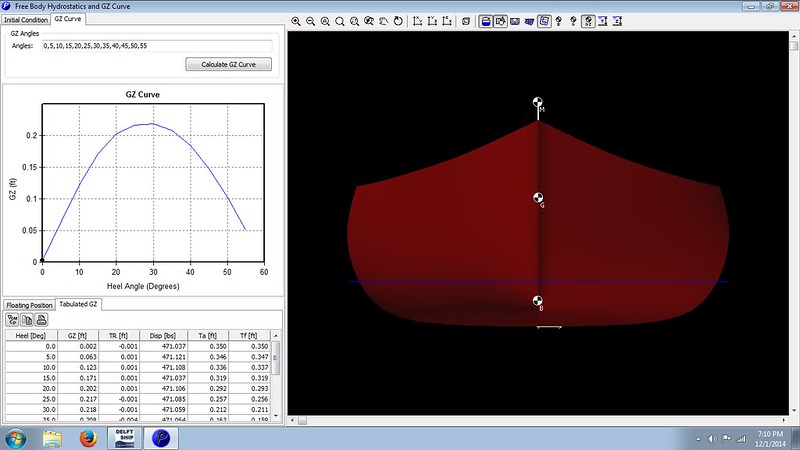

These are the stability curves. The graph on the left shows the resistance to tipping at different angles of heal. In the second picture I tipped the hull to where water is about ready to spill over the gunwales, which is the point of maximum resistance.

V4 stability by Alan Gage, on Flickr

V4 stability by Alan Gage, on Flickr

V4_2 stability by Alan Gage, on Flickr

V4_2 stability by Alan Gage, on Flickr

Again, it's difficult to reconcile digital with reality. All I can say for sure is that it's a lot more stable than the solo I just built, but how these numbers compare with reality I don't know. But judging by the hull shape I should be erring on the side of too stable rather than too tippy. This boat has more resistance to tipping at 5 degrees than my most recent solo had at its maximum.

Thinking 3/16" strips with 4oz glass and a double layer below the waterline both inside and out. Trim will be cherry and I might keep the gunwales less than the standard 3/4" and hang the seats from cleats attached to the hull rather than from the inwale. We'll see. Unfortunately the boat isn't likely to see water more than a couple times/year and only short outings in calm water at that.

Alan

There will be some more tweaking but the design is getting close. 17'x35" max, 33" WL, 33.5" gunwale

Desmoines_v4_Linesplan by Alan Gage, on Flickr

Desmoines_v4_Linesplan by Alan Gage, on FlickrThese are the stability curves. The graph on the left shows the resistance to tipping at different angles of heal. In the second picture I tipped the hull to where water is about ready to spill over the gunwales, which is the point of maximum resistance.

V4 stability by Alan Gage, on Flickr

V4 stability by Alan Gage, on Flickr V4_2 stability by Alan Gage, on Flickr

V4_2 stability by Alan Gage, on FlickrAgain, it's difficult to reconcile digital with reality. All I can say for sure is that it's a lot more stable than the solo I just built, but how these numbers compare with reality I don't know. But judging by the hull shape I should be erring on the side of too stable rather than too tippy. This boat has more resistance to tipping at 5 degrees than my most recent solo had at its maximum.

Thinking 3/16" strips with 4oz glass and a double layer below the waterline both inside and out. Trim will be cherry and I might keep the gunwales less than the standard 3/4" and hang the seats from cleats attached to the hull rather than from the inwale. We'll see. Unfortunately the boat isn't likely to see water more than a couple times/year and only short outings in calm water at that.

Alan