Some of you who have known me for a long time might be thinking that I'm getting soft or sumpin. Well, truth is, I live the good life, don't stop myself from too many urges when it comes to eating and liquor and stuff, and as a result, my body is slowly decomposing into a blubbery mass of laziness. Don't get me wrong, I can still paddle and port with the big boys, but those midnight cramps that make me scream like a ten year old girl are best left to a solo trip.

So I've been thinking about a square stern for a year or two, especially for moose hunting, where the object is to hunt moose (er, or maybe drink beer) with canoes, but not have to paddle a lot. This fall, my buddy and I paddled about ten kilometers into 50 kph headwinds, and it was a mean way to start a trip that was supposed to have us sitting around the fire till the wee hours, bullshitting and drinking. Think we both ended up in bed by 9:00 PM that night.

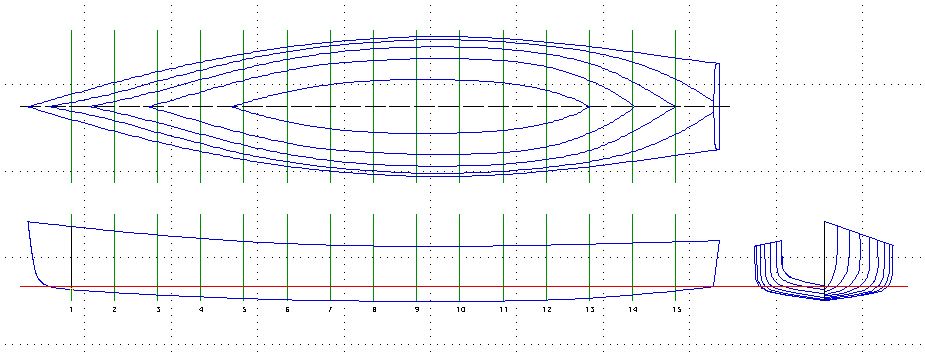

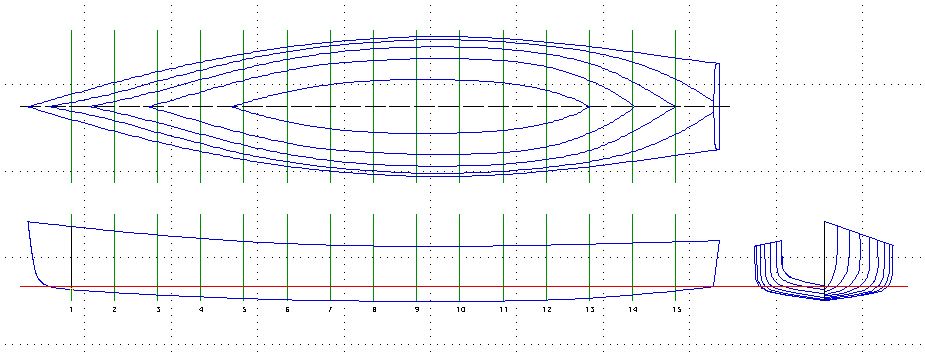

After wasting a lot of money, I finally came upon a plan that I think will work, from Martin and John Winters at Greenval.com. It's called the Nipissing. Here's the layout.

I'm putting the stations at 13.5 inches, so it will be a little more than 17 and a half feet. Small enough to still portage a mile or two, but with it's girthy mid section, big enough to haul a moose.

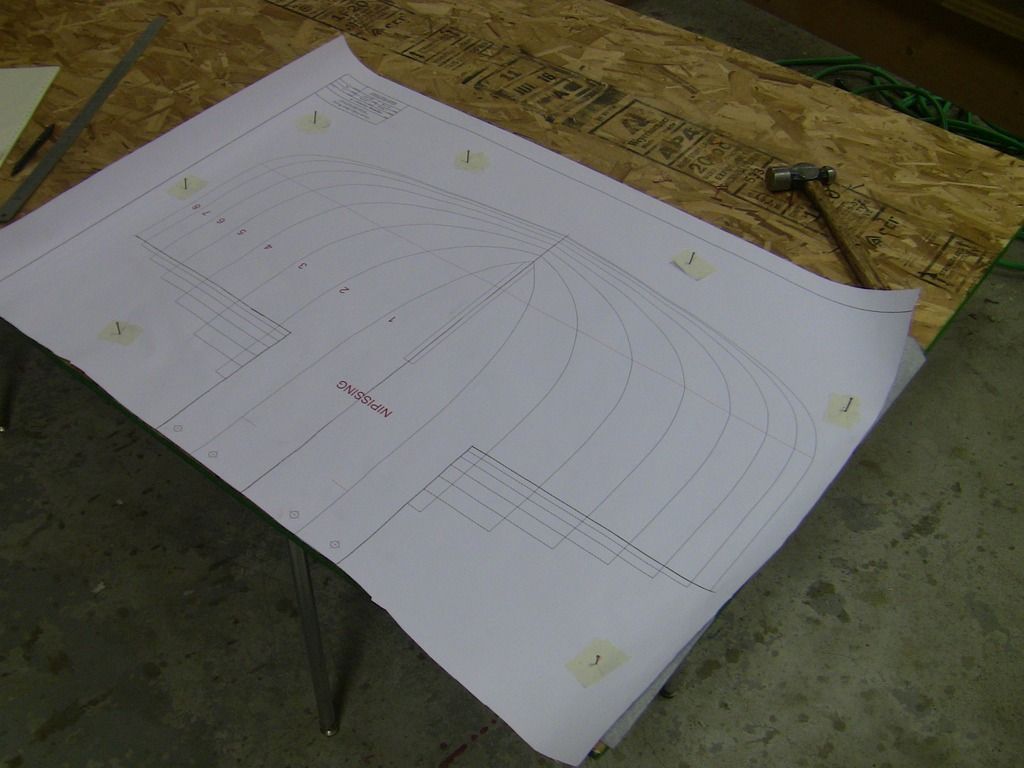

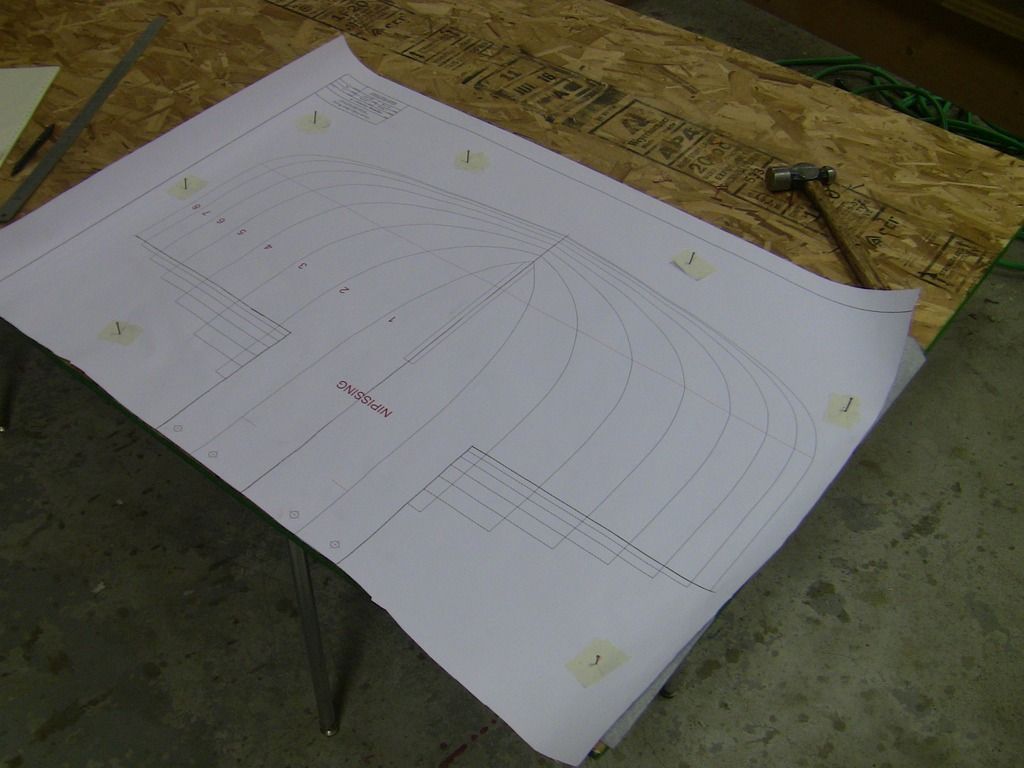

I started tracing the stations out a couple of days ago. Here's the bow forms -

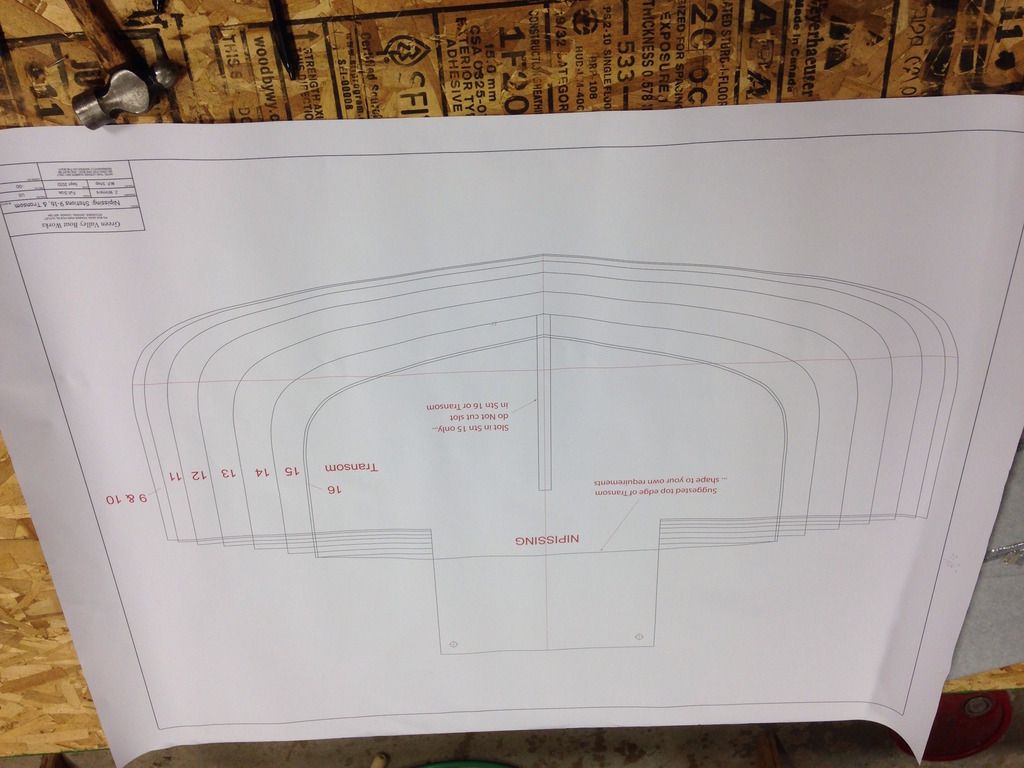

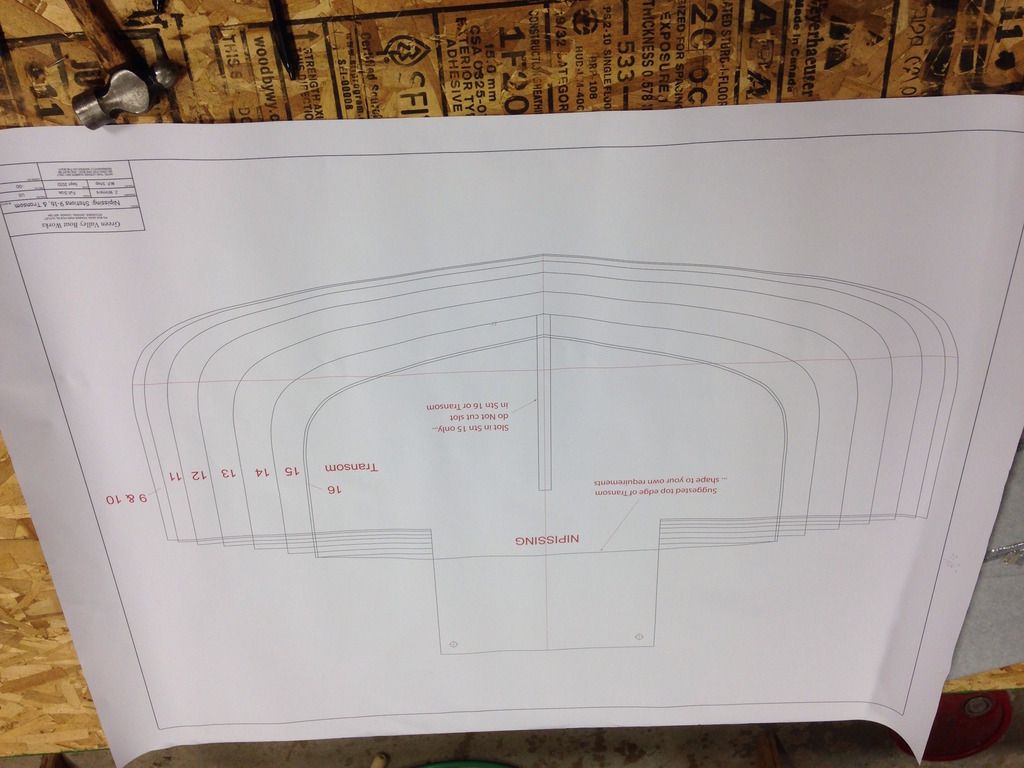

Here's the stern, which should prove interesting. The transom detail is pretty good, and there is a stern form included with the proper angles all figured out.

I got this little baby for 20 bucks, got carb kit coming in next week. My father-in-law is redoing a little Evinrude 1.5 for me too.

I'm looking forward to doing lots of exploring this spring with this new setup. This isn't gonna be an Alan Gage build, gonna take me a while, haven't even got cedar yet. Think I'll use one sheet of ten ounce glass for both inner and outer hull on this one, I had good luck with that stuff on a 20 footer I built.

So I've been thinking about a square stern for a year or two, especially for moose hunting, where the object is to hunt moose (er, or maybe drink beer) with canoes, but not have to paddle a lot. This fall, my buddy and I paddled about ten kilometers into 50 kph headwinds, and it was a mean way to start a trip that was supposed to have us sitting around the fire till the wee hours, bullshitting and drinking. Think we both ended up in bed by 9:00 PM that night.

After wasting a lot of money, I finally came upon a plan that I think will work, from Martin and John Winters at Greenval.com. It's called the Nipissing. Here's the layout.

I'm putting the stations at 13.5 inches, so it will be a little more than 17 and a half feet. Small enough to still portage a mile or two, but with it's girthy mid section, big enough to haul a moose.

I started tracing the stations out a couple of days ago. Here's the bow forms -

Here's the stern, which should prove interesting. The transom detail is pretty good, and there is a stern form included with the proper angles all figured out.

I got this little baby for 20 bucks, got carb kit coming in next week. My father-in-law is redoing a little Evinrude 1.5 for me too.

I'm looking forward to doing lots of exploring this spring with this new setup. This isn't gonna be an Alan Gage build, gonna take me a while, haven't even got cedar yet. Think I'll use one sheet of ten ounce glass for both inner and outer hull on this one, I had good luck with that stuff on a 20 footer I built.