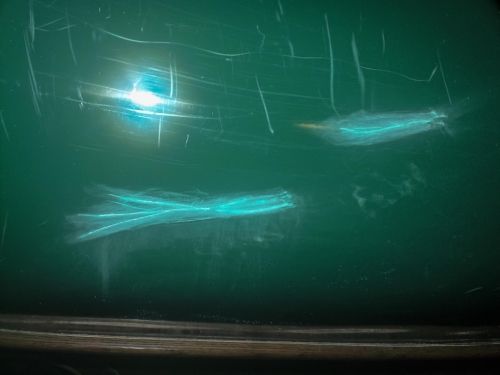

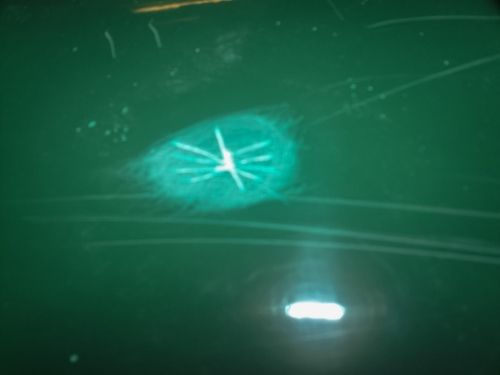

So in my interdiction I had said I was going to start agel-coat repair project on my Lincoln Explorer canoe. I called Lincoln and theygave me the part/color number for the gel-coat and told me that I could get itat any marine store. OK maybe in Maine you have a marine parts shop on everyblock but in Portland, OR no one had it. So I called Lincoln back and they willsale gel-coat state to you. I got the MEKP catalyst (epoxy hardener) at HomeDepot with 200, 400 and 600 wet-dry sandpaper and Acetone. Tonight I’m justrunning a test on the gel-coat I mixed ½ TBS to 2 drops of MEKP catalyst tomake shire the gel-coat set. If everything goes well I’ll be preparing the areason the canoe for the gel-coat tomorrow. Here is the instruction that Lincoln sent me for doing they repairs.

1. Prepared the area - remove the gelcoat chips from theedges of the damaged area. For smaller damage, us a utility knife to scratchout, slightly deepen cracks/scratches. Sand the area immediately around thedamaged area using 100 - 120 dry sand paper. Then clean thoroughly with acetoneor lacquer thinner.

2. Prepare the gelcoat - You'll need to pick up MEKP, thecatalyst. Measure required amount of gelcoat into a paper cup. Add catalyst(MEKP) at the rate of 4-5 drops per tablespoon of gelcoat (2 %). Mix thoroughlyfor about a minute. If desired the gel can be thickened using Cab-O-Cil, a veryfine, fluffy-light material. It will not change the color of the gel. Mix itVERY well!

3. Apply the Gel-Coat - Apply the mixture immediately to theprepared area using the mixing paddle or your finger (wear a glove) as aspreader. Spread the mixture into the repair area. Then use the utility bladeand acetone to remove excess and cover the area with celophane or wax paper.Use masking paper to keep in place. Allow the repair to sit for 2-4 hours(overnight is ideal) until hardened.

4. Wet-Sand to smooth - After the coat has set, wet sand thearea using wet and dry paper with wood for back up. Start with 400 grit and uselots of water. Sand until patch is almost level and blends with the surroundingarea. Finish wet-sanding using 600-grit.

5. Polish the area - Polish the patched area with a roughhand rubbing compound, any automobile type rubbing compound will work, untilthe original luster is restored using hand or electric polisher. For the finalgloss, use a liquid or paste car wax.

Here is a good YouTube video on gel-coat repairs.

1. Prepared the area - remove the gelcoat chips from theedges of the damaged area. For smaller damage, us a utility knife to scratchout, slightly deepen cracks/scratches. Sand the area immediately around thedamaged area using 100 - 120 dry sand paper. Then clean thoroughly with acetoneor lacquer thinner.

2. Prepare the gelcoat - You'll need to pick up MEKP, thecatalyst. Measure required amount of gelcoat into a paper cup. Add catalyst(MEKP) at the rate of 4-5 drops per tablespoon of gelcoat (2 %). Mix thoroughlyfor about a minute. If desired the gel can be thickened using Cab-O-Cil, a veryfine, fluffy-light material. It will not change the color of the gel. Mix itVERY well!

3. Apply the Gel-Coat - Apply the mixture immediately to theprepared area using the mixing paddle or your finger (wear a glove) as aspreader. Spread the mixture into the repair area. Then use the utility bladeand acetone to remove excess and cover the area with celophane or wax paper.Use masking paper to keep in place. Allow the repair to sit for 2-4 hours(overnight is ideal) until hardened.

4. Wet-Sand to smooth - After the coat has set, wet sand thearea using wet and dry paper with wood for back up. Start with 400 grit and uselots of water. Sand until patch is almost level and blends with the surroundingarea. Finish wet-sanding using 600-grit.

5. Polish the area - Polish the patched area with a roughhand rubbing compound, any automobile type rubbing compound will work, untilthe original luster is restored using hand or electric polisher. For the finalgloss, use a liquid or paste car wax.

Here is a good YouTube video on gel-coat repairs.

Last edited: