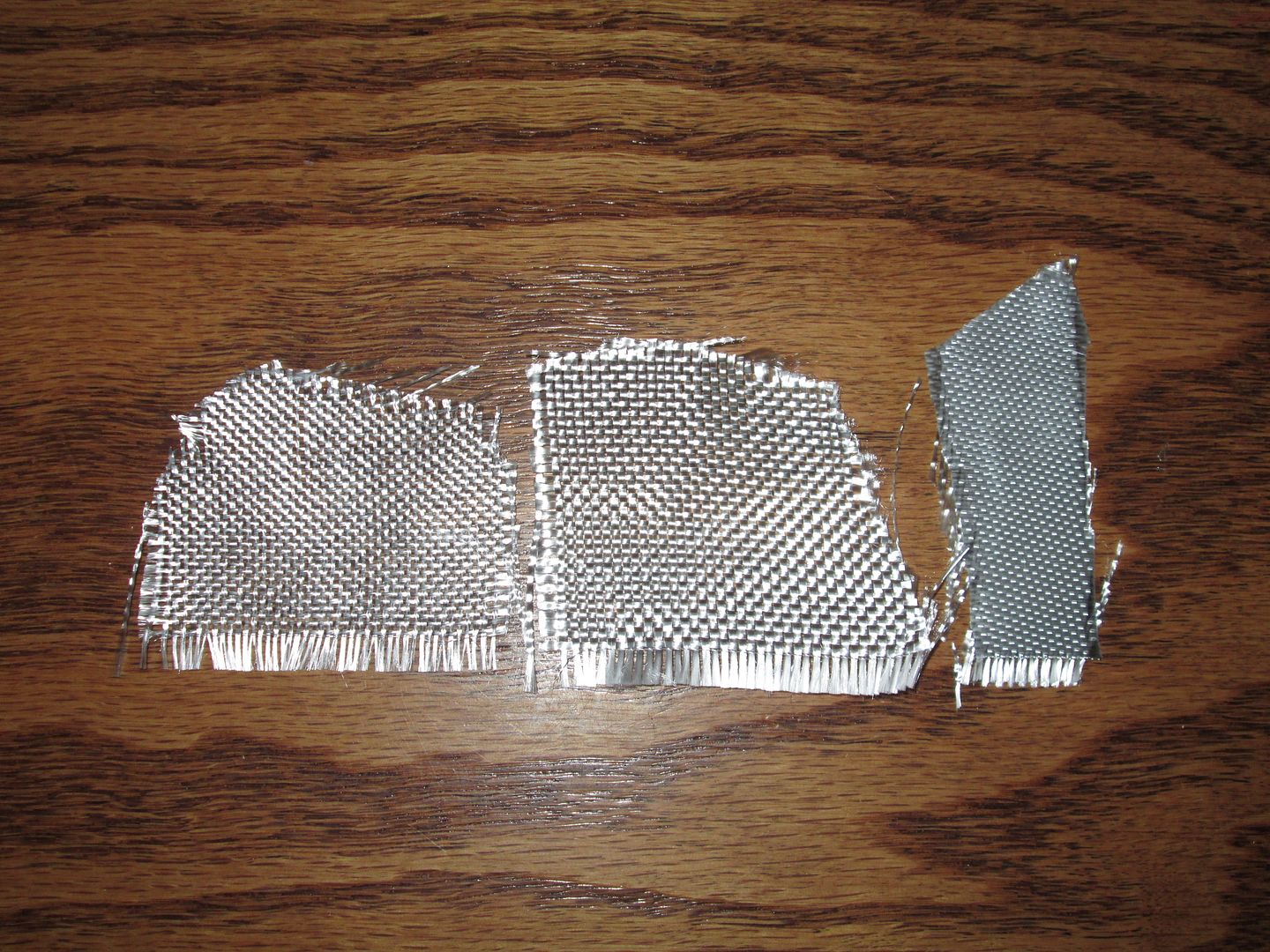

Sounds like a good sturdy layup. I like the thin layer of glass on the inside. Gives you something to sand into without immediately fuzzing the kevlar.

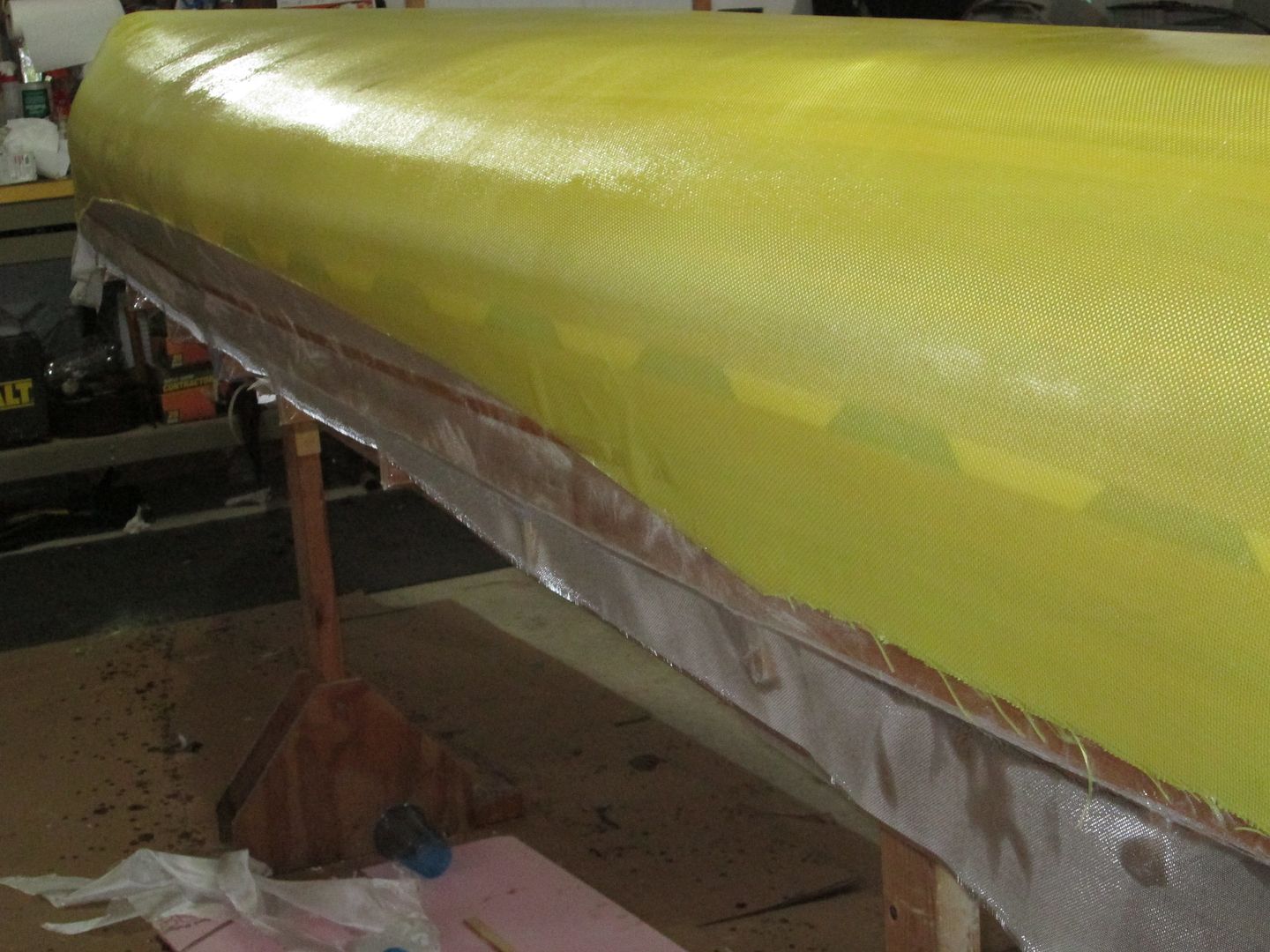

How do you attach your shrink film to the mold? That was always a pain when I did it. The best solution I came up with was attaching a wood strip all along the underside of the stations, one on each side, and then attach double stick tape the whole length. I also put a strip of double stick tape down the keel. With help I'd stretch and lay out the film over the length of the boat and then run down the length and attach to the bottom of the mold. For the stems which I attach last, I leave a section of double stick with the paper on until everything else is in place, then stretch the film over from one side, trim, apply another strip of tape, pull the other side of the shrink over and stick it, and one final trim.

Thats a long winded response, hope it makes sense. It also a little late, but for anyone else or if you do it again sometime, it will make a wrinkle free mold release wrap. And, Duck brand is the only film I will use.

How do you attach your shrink film to the mold? That was always a pain when I did it. The best solution I came up with was attaching a wood strip all along the underside of the stations, one on each side, and then attach double stick tape the whole length. I also put a strip of double stick tape down the keel. With help I'd stretch and lay out the film over the length of the boat and then run down the length and attach to the bottom of the mold. For the stems which I attach last, I leave a section of double stick with the paper on until everything else is in place, then stretch the film over from one side, trim, apply another strip of tape, pull the other side of the shrink over and stick it, and one final trim.

Thats a long winded response, hope it makes sense. It also a little late, but for anyone else or if you do it again sometime, it will make a wrinkle free mold release wrap. And, Duck brand is the only film I will use.

Last edited: