Glenn, G Flex thickened with colloidal silica powder is exactly what I would use as a filler and sealant for the foam core as I mentioned earlier in the thread. I have never used Gorilla Glue but I know quite a few people who have and claim good results with it. But then, I have heard people claim good results with just about anything that can be stuck in a hole, including JB Weld, Marine Goop, polyester auto body putty, you name it. But if you are going to apply a fiberglass patch at all, G Flex is the best epoxy for ABS, and if you are going to use it for patching over the hole, why not use it to fill the hole?

In reality, a quarter sized hole in many locations of a hull that is not subject to high stress or abrasion could probably be filled with just about anything, including bubble gum, so long as it was waterproof. My preference is to use some type of cloth for any through and through hole bigger than 1/4" or so. The method I first described, a concentric laminated cloth repair, might be thought to be overkill but will result in a very strong repair and really sounds much more complicated to describe than it is to do.

Here is a West System video describing the process:

http://www.youtube.com/watch?v=6N7YMr6E564&t=210s

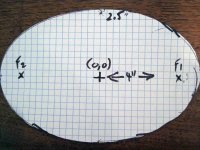

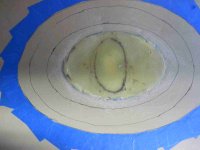

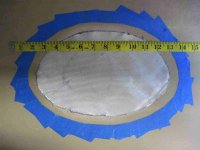

The video recommends using a shallow angle bevel of 1:12. I would probably use a less shallow bevel for a hole of this size, maybe 1:8 or 1:10. With a dremel and an appropriate grinding tip, beveling can be accomplished pretty quickly. You just measure the thickness of the hull at the site of the hole, multiply that by whatever bevel ratio you prefer to use, and mark a circle around the hole accordingly. So if the hull is 3/8" thick at the hole, and your bevel ratio was 1:8, you would mark out a circular perimeter 3" from the margins of the hole all the way around. Then take your dremel and make a smooth bevel from the hole margin out to the perimeter of the circle.

The video also show wetting out all layers of the patch simultaneously. G Flex epoxy is rather viscous and I would generally not recommend trying this as I suspect it might result in air voids. But you can cut out all the layers and apply the next one as soon as the epoxy of the preceding layer has cured to a tack. So you can really complete the whole repair in an afternoon. The video also recommends applying the biggest patch first. I honestly don't believe the order big to small, or small to big, makes any difference from a structural standpoint. I think it would be easier to get the cloth to lay down smoothly against the exterior of the hull and the foam core by applying the smallest patch first and working from small to large. But either way will work. The idea is that the margins of each patch are bonded directly to the ABS.