Hi All – I have a question for all of you who have used kevlar fabric in a build. I bought plans for my next build which will be a JEM Northwind, aka Kruger Seawind just like Deerfly built last year. A good friend has a Kruger and I'm convinced. I’m taking advantage of some of the things Deerfly learned with his build including his fabric tests. This boat will be for big waters like ocean, big lakes, big rivers. I want to get rid of my sea kayak, so this will replace that for me. I’m currently at the point where I need to get rid of a boat to get a new boat.

Since I don’t really plan to ever have to portage this canoe very far, I’d like to build it strong without adding any unnecessary weight. I’ll use 1/4” strips and plan to sheath with 5oz kevlar inside and out on the hull with 4 or 6 oz. S-glass over over the outside for a layer to sand. Outside of the hull will be painted white. I’ll use kevlar underneath the deck, which will be constructed using 3/16” strips and possibly finish the top clear, probably using 6 oz e-glass.

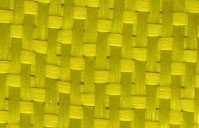

My question is regarding which kevlar to choose. It seems that 5 oz kevlar comes in plain weave, twill weave and 4 harness satin weave. Does anybody have a good explanation of the difference in these in terms of strength, ease of wetout or any other important factors worth considering?

Should I add the sandable layer on the inside of the boat (bottom of hull and under the deck) ?

I’m in the planning stages at the moment and will probably won’t actually build the boat until this winter, but I’ll need to make more strips, cut forms and do other prep work as time allows into the fall.

Thanks, Mark

Since I don’t really plan to ever have to portage this canoe very far, I’d like to build it strong without adding any unnecessary weight. I’ll use 1/4” strips and plan to sheath with 5oz kevlar inside and out on the hull with 4 or 6 oz. S-glass over over the outside for a layer to sand. Outside of the hull will be painted white. I’ll use kevlar underneath the deck, which will be constructed using 3/16” strips and possibly finish the top clear, probably using 6 oz e-glass.

My question is regarding which kevlar to choose. It seems that 5 oz kevlar comes in plain weave, twill weave and 4 harness satin weave. Does anybody have a good explanation of the difference in these in terms of strength, ease of wetout or any other important factors worth considering?

Should I add the sandable layer on the inside of the boat (bottom of hull and under the deck) ?

I’m in the planning stages at the moment and will probably won’t actually build the boat until this winter, but I’ll need to make more strips, cut forms and do other prep work as time allows into the fall.

Thanks, Mark