After the better part of a year looking on the used market for just the right solo canoe, I opted to purchase new rather than wait for an uncertain future time I might happen upon one.

Buying local is my preference, but my local dealer was not able to get me in the canoe to demo it. Searching I found one in Annapolis I could test paddle.

My timing was good. As I made plans to head north to Annapolis and a test paddle, I became aware of the Western PA Solo Canoe Rendezvous where a vast number of solo canoes would be available to test paddle. Hmmmm....this called to my retired side - a ROAD TRIP!! So I took the better part of a week, in a huge looping drive around the mid Atlantic states, in search of my next solo canoe.

I have soloed for many years. but it has always been in a tandem, flipped around. It was quite a treat to get in a canoe designed with only one paddler in mind. After paddling about 10-12 canoes in western PA, I settled on the one I had test paddled in Annapolis - a Wenonah Wilderness in the ultra light Kevlar construction.

The canoe had to be built (the test canoe was a heavier gelcoat layup) so in early June it was ordered. Mid July it arrived in Annapolis and I planned another trip north to pick it up.

Suspecting Mike McCrea's would love a shop day tinkering with a brand new canoe and little need for messy epoxy work, I dangled the carrot of opportunity in front of him to help me outfit the new canoe. That bait had barely struck the surface before Mike struck and swallowed it whole. So on a Monday in July I picked the canoe up in Annapolis and headed for Mike's workshop in northern Maryland.

The following will illustrate the outfitting we did on the canoe. It's not at the level of master craftsmanship that others in this forum have shared in their building and repairing of boats, but it may prove useful to others looking for ideas on what to do with their boats. Along with Mike, Dave I (04) and Conk shared their work on canoe outfitting with me, and it was a delight to have so many ideas to work with.

Mike and I worked pretty much non-stop in the effort to get the canoe on the water as soon as possible and we set no time aside for photos. I would have stayed longer, but Mike was caught fondling a rudder near my canoe and I became fearful my canoe might sprout a rear appendage if I lingered too long. Since then I've returned home to further refine my canoe outfitting and I have time to photo document the outfitting of my canoe.

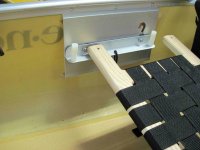

Deck plate shock cord retainer for painter

Dressing the end of a line with heat shrink tubing - thanks Mike!

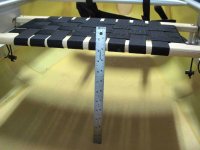

Velcro paddle restraint - thanks to Conk for this idea

MORE TO FOLLOW

Buying local is my preference, but my local dealer was not able to get me in the canoe to demo it. Searching I found one in Annapolis I could test paddle.

My timing was good. As I made plans to head north to Annapolis and a test paddle, I became aware of the Western PA Solo Canoe Rendezvous where a vast number of solo canoes would be available to test paddle. Hmmmm....this called to my retired side - a ROAD TRIP!! So I took the better part of a week, in a huge looping drive around the mid Atlantic states, in search of my next solo canoe.

I have soloed for many years. but it has always been in a tandem, flipped around. It was quite a treat to get in a canoe designed with only one paddler in mind. After paddling about 10-12 canoes in western PA, I settled on the one I had test paddled in Annapolis - a Wenonah Wilderness in the ultra light Kevlar construction.

The canoe had to be built (the test canoe was a heavier gelcoat layup) so in early June it was ordered. Mid July it arrived in Annapolis and I planned another trip north to pick it up.

Suspecting Mike McCrea's would love a shop day tinkering with a brand new canoe and little need for messy epoxy work, I dangled the carrot of opportunity in front of him to help me outfit the new canoe. That bait had barely struck the surface before Mike struck and swallowed it whole. So on a Monday in July I picked the canoe up in Annapolis and headed for Mike's workshop in northern Maryland.

The following will illustrate the outfitting we did on the canoe. It's not at the level of master craftsmanship that others in this forum have shared in their building and repairing of boats, but it may prove useful to others looking for ideas on what to do with their boats. Along with Mike, Dave I (04) and Conk shared their work on canoe outfitting with me, and it was a delight to have so many ideas to work with.

Mike and I worked pretty much non-stop in the effort to get the canoe on the water as soon as possible and we set no time aside for photos. I would have stayed longer, but Mike was caught fondling a rudder near my canoe and I became fearful my canoe might sprout a rear appendage if I lingered too long. Since then I've returned home to further refine my canoe outfitting and I have time to photo document the outfitting of my canoe.

Deck plate shock cord retainer for painter

Dressing the end of a line with heat shrink tubing - thanks Mike!

Velcro paddle restraint - thanks to Conk for this idea

MORE TO FOLLOW