It's hard to do accurately. I used to mix my epoxy using a small, analog, kitchen scale. But I'd always run out of resin before hardener so I figured I better come up with something more accurate.

I've got pumps for some of my epoxy but even the minimum number of full pumps is way too much epoxy for many jobs and I hate to waste it. Eyeballing partial pump squirts can work but that gets dicey. This is what I've been doing the last last few boats and it's worked well so far. Today I wanted to mix up about 1 1/2 ounces, which is roughly 45ml. My epoxy is a 2:1 ratio so that's 3 parts total. To get 45ml that means I need 15ml of hardener and 30ml of resin.

I start with a very small measuring cup and pour in 15ml of water.

20141218_001 by Alan Gage, on Flickr

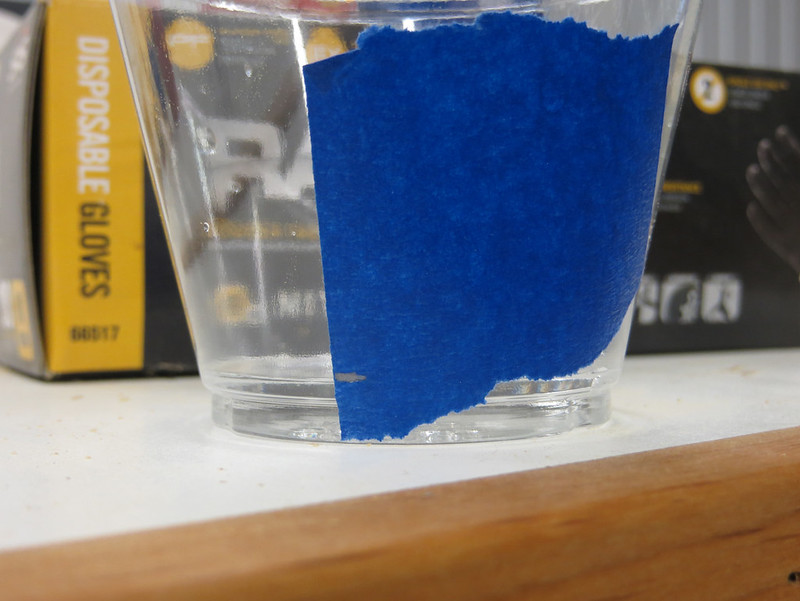

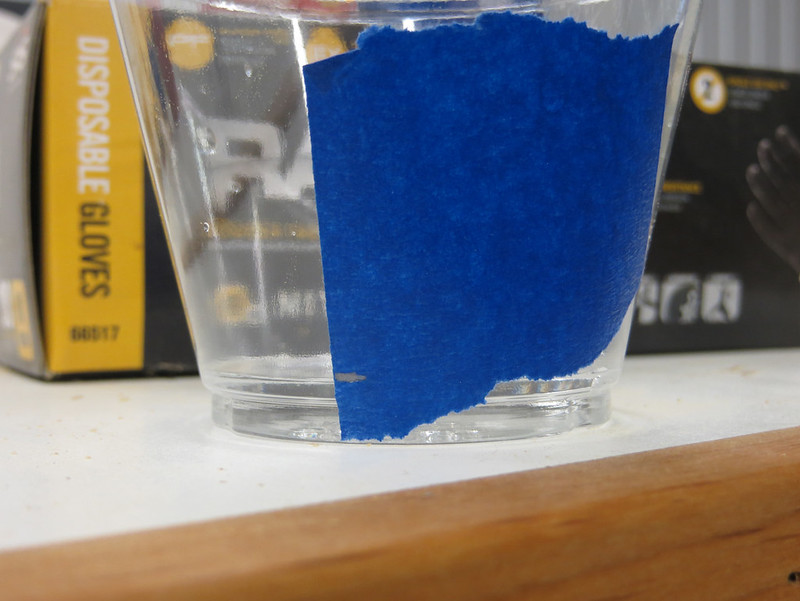

That water gets dumped into my mixing cup, onto which I've put a piece of tape. Put a mark on the tape at the 15ml waterline. White tape works better but it appears I'm out.

20141218_002 by Alan Gage, on Flickr

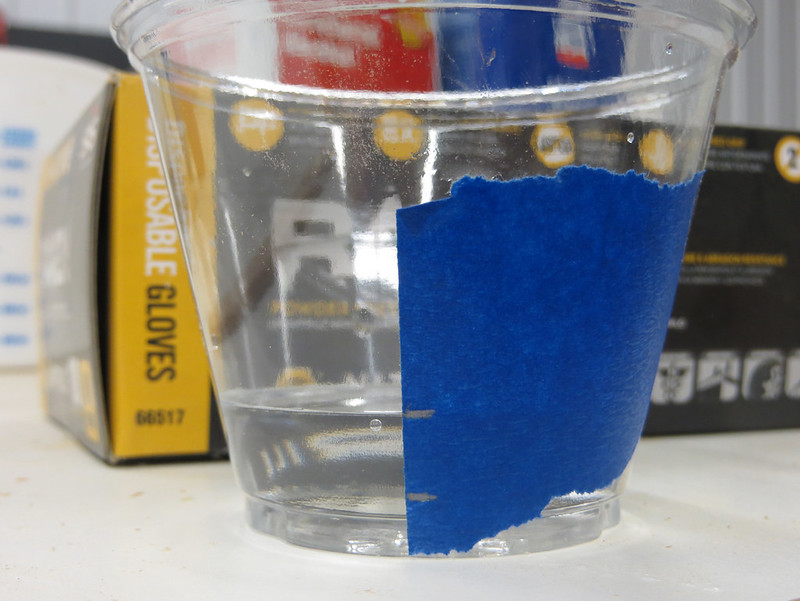

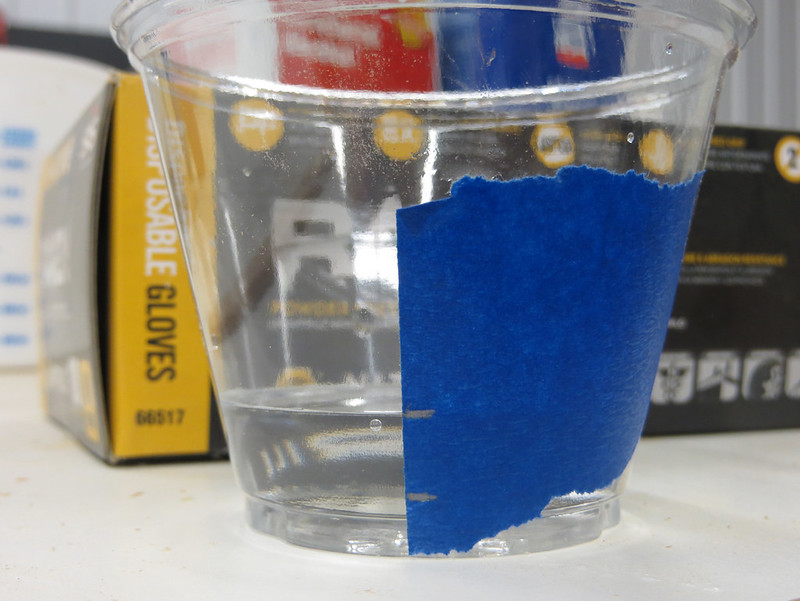

Pour that water back into the measuring cup and then fill the measuring cup to 45ml. Now dump all the water back into the cup and mark a second line on the tape:

20141218_003 by Alan Gage, on Flickr

Now throw out the water and dry the inside of the cup. Fill to the first line with hardener and then top it off to the second line with resin.

45ml is about as small as I can go while still maintaining enough accuracy for it to setup properly each time. It only takes a small error in volume to throw the mix off considerably with these low doses. The larger the batches the more accurate it is.

Reason for the small batch today was that it was thickened and tinted to fill any gaps before fiberglassing the stripper I'm working on.

Anyone got a different/better way?

Alan

I've got pumps for some of my epoxy but even the minimum number of full pumps is way too much epoxy for many jobs and I hate to waste it. Eyeballing partial pump squirts can work but that gets dicey. This is what I've been doing the last last few boats and it's worked well so far. Today I wanted to mix up about 1 1/2 ounces, which is roughly 45ml. My epoxy is a 2:1 ratio so that's 3 parts total. To get 45ml that means I need 15ml of hardener and 30ml of resin.

I start with a very small measuring cup and pour in 15ml of water.

20141218_001 by Alan Gage, on Flickr

That water gets dumped into my mixing cup, onto which I've put a piece of tape. Put a mark on the tape at the 15ml waterline. White tape works better but it appears I'm out.

20141218_002 by Alan Gage, on Flickr

Pour that water back into the measuring cup and then fill the measuring cup to 45ml. Now dump all the water back into the cup and mark a second line on the tape:

20141218_003 by Alan Gage, on Flickr

Now throw out the water and dry the inside of the cup. Fill to the first line with hardener and then top it off to the second line with resin.

45ml is about as small as I can go while still maintaining enough accuracy for it to setup properly each time. It only takes a small error in volume to throw the mix off considerably with these low doses. The larger the batches the more accurate it is.

Reason for the small batch today was that it was thickened and tinted to fill any gaps before fiberglassing the stripper I'm working on.

Anyone got a different/better way?

Alan