G

Guest

Guest

Shop partner Joel has been wanting to put a rudder on his Wenonah Rendezvous for a couple of years now. Today we had at it.

Joel had picked up a set of gudgeons from Duckworks, but aside from that $15 piece everything else would need to be made or fabricated from stuff in the shop.

http://www.duckworksbbs.com/hardware...anoe/index.htm

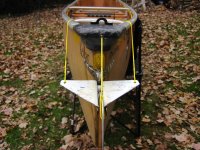

A little trial and error tape in place and we calculated the best position for the gudgeon.

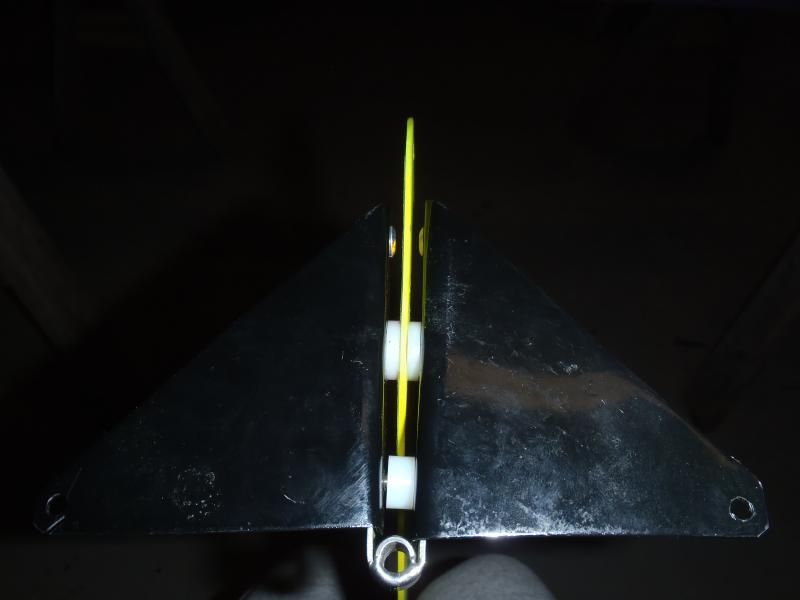

The gudgeon needed control arms. Easily fabricated by cutting two triangles from an old aluminum sign and bending a right angle flap on each.

We use the lauan rudder template (Kruger shaped) from the Optima rebuild and it was the perfect size and shape with no additional modification.

A little more saw work and presto, a rudder.

A nicely reflective rudder at that (at least on one side)

A couple of nylon washers and spacers and that puppy works like a charm.

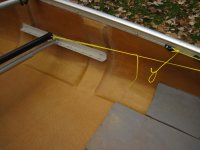

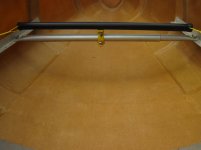

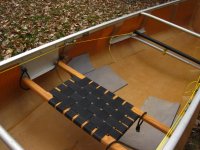

Instead of installing foot pedals Joel wanted to use a pivoting bar attached to the existing foot brace. Because the two sleeved tubes of the foot brace slide during adjustment we couldn’t simply drill a pivot through the foot brace. It needed something trickier.

Something odd. Something something.

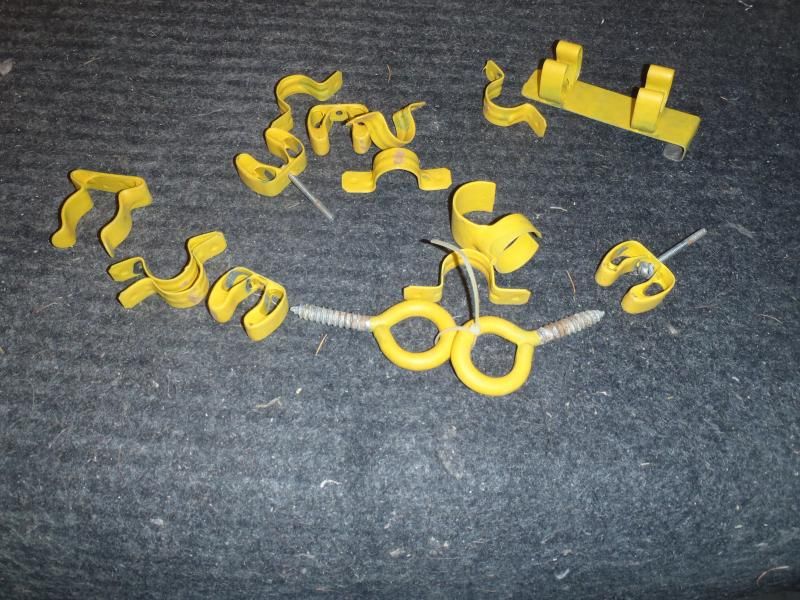

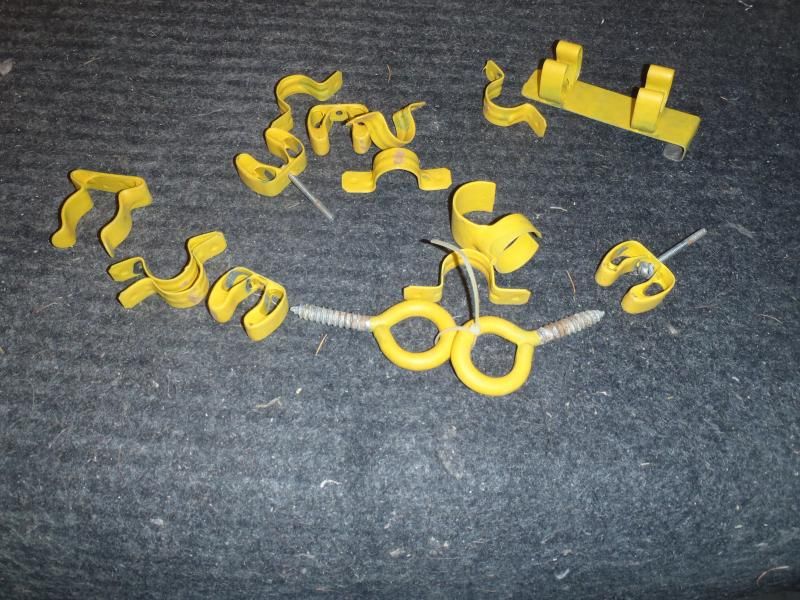

20 years ago I had a can of Plastic dip, and knowing it would harden I used it up dipping various objects. Many of which I still have.

This little tool hanger proved to be the ideal solution.

That was some seriously tough spring steel, and we wore out a couple of drill bits making the needed hardware holes. For the rudder control bar we use a piece of anodized aluminum tubing from a rec kayak rebuild

We faked some lines on the control bar and Joel had a test sit in the Rendezvous. He can still lock in on the foot brace and move the rudder with his toes.

The rudder and foot controls are lightweight, easily removable and re-installed and the total cost was less than $20 and a couple of hours in the shop.

I hope to see that rudder in action next week in the Carolinas and later this winter in the Everglades. And when Joel has it tweaked to perfection we’re putting one on my Penobscot.

Joel had picked up a set of gudgeons from Duckworks, but aside from that $15 piece everything else would need to be made or fabricated from stuff in the shop.

http://www.duckworksbbs.com/hardware...anoe/index.htm

A little trial and error tape in place and we calculated the best position for the gudgeon.

The gudgeon needed control arms. Easily fabricated by cutting two triangles from an old aluminum sign and bending a right angle flap on each.

We use the lauan rudder template (Kruger shaped) from the Optima rebuild and it was the perfect size and shape with no additional modification.

A little more saw work and presto, a rudder.

A nicely reflective rudder at that (at least on one side)

A couple of nylon washers and spacers and that puppy works like a charm.

Instead of installing foot pedals Joel wanted to use a pivoting bar attached to the existing foot brace. Because the two sleeved tubes of the foot brace slide during adjustment we couldn’t simply drill a pivot through the foot brace. It needed something trickier.

Something odd. Something something.

20 years ago I had a can of Plastic dip, and knowing it would harden I used it up dipping various objects. Many of which I still have.

This little tool hanger proved to be the ideal solution.

That was some seriously tough spring steel, and we wore out a couple of drill bits making the needed hardware holes. For the rudder control bar we use a piece of anodized aluminum tubing from a rec kayak rebuild

We faked some lines on the control bar and Joel had a test sit in the Rendezvous. He can still lock in on the foot brace and move the rudder with his toes.

The rudder and foot controls are lightweight, easily removable and re-installed and the total cost was less than $20 and a couple of hours in the shop.

I hope to see that rudder in action next week in the Carolinas and later this winter in the Everglades. And when Joel has it tweaked to perfection we’re putting one on my Penobscot.

Last edited: