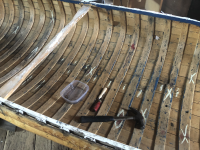

I picked up another Chestnut restoration project recently. The seller presented it as a "pre-fire Chestnut Bobs Special". Now that I've had it a while, and started working on it, I'm thinking it's a Chestnut Ranger- one of their Prospector series of canoes. It measures 15' x 35" x 13.5" deep. Bobs were consistently offered at 37" wide and 12" deep.

While searching Google, I came across this post from Canoetripping:

I was gratified to hear Bob B.'s remarks on his Ranger (built by Headwaters, but on an original Chestnut form). It'll be a long time before this ugly duckling sees water but it should be worth the wait!

While searching Google, I came across this post from Canoetripping:

Picked up my Headwaters Canoe! Pic heavy post.

Alright!! I picked up my 15 foot Headwaters Prospector - basically a Chestnut Ranger - and after driving 1000 miles this weekend to bring her home, I took my first paddle with her yesterday for 5 hours on the Wisconsin River. It was a beautiful day and evening, but the current was pretty strong...

www.canoetripping.net

I was gratified to hear Bob B.'s remarks on his Ranger (built by Headwaters, but on an original Chestnut form). It'll be a long time before this ugly duckling sees water but it should be worth the wait!