A few weeks ago I convinced my wife that I needed to build another strip canoe this winter since I didn't want everything I learned on my first canoe build to go to waste. Since I'm always checking craigslist for canoe related stuff, I came across this canoe. The wording of the ad said that the fellow was interested in getting this boat to someone who would restore it, since he had owned it since the early 1960's. It had a low price, and didn't look too bad from the pictures, but before I went and looked at it, I was able to find the build record for this boat, a 1928 Old Town HW model, 16 feet. The boat came from a campfire girls camp near Arden, NY. A quick search online and I found old postcards and photos of this very model of canoe on the lake there in the early 1930's. OK, now I'm really interested.

I drove over through Bozeman and met the fellow at his home and took a good look at the boat. As you'll see from the photos it needs lots of work. I think the fiberglass will come off easy enough, it already sounds like it's mostly separated from the wood. The inside is painted with latex, which will mostly come off with a fingernail. It has lots of broken or cracked ribs, perhaps 16, perhaps more? One inwale is in need of replacement (for some reason the other one is solid as a rock), as well as some amount of planking along the bottom of the boat. The rear seat is partially original as are the thwarts. The front seat is garbage. The decks have some rot near the tips and may be salvageable. I'm sure there's rot up under the stem tips, but looking under the decks it may not be excessive. The canoe is still pretty straight, which the fiberglass is surely responsible for. This boat probably would have gone to the dump long ago if it hadn't been glassed.

I paid the man the couple hundred dollars he was asking. At this point he said that if I actually do a restoration he'll give me the money back. I accepted his offer and added that we would go for a paddle in the canoe when I am done.

Here are some photos of its current condition. At least I can take it out for a paddle before I start to rip into it later this fall.

I really like the shape of the stems on this canoe.

This canoe was fiberglassed in the mid 1960's, and the fellow said the resin was setting as he was putting it on the boat. Hopefully that means an easier time for me getting it off. I think the glass and resin added a good 20 pounds to the boat.

The inwale and outwale on one side are shot. The canoe must have always been sitting on the ground on this side. The wood on the other side is in good shape. I'll try to find some spruce to replace the inwale.

The decks are in OK shape with a little rot near the tips. Hopefully I'll be able to save them. I'm not sure what those bolts were for.

Quite a number of broken or cracked ribs. A couple of the ribs have had these chunks replaced. The planking looks pretty bad on the bottom.

Original Build Record from Old Town. I think there's a lot more to find out about the history of this canoe from this document.

This is a 1931 photo of the camp where this canoe was delivered in 1928. All of these boats appear to be the same HW model as mine. My canoe may be in this photo.

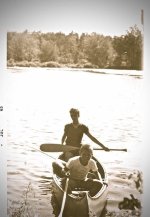

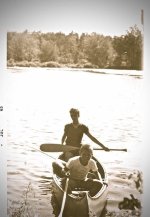

This is the canoe in 1963. It still had canvas on it in this photo. The fiberglass was put on a few years later. When I picked up the boat, the fellow showed me the paddle he is holding in the stern.

Well, I seem to have quite a job ahead of me with this one. After finding all this history on the boat, and taking into account it turned 88 years old last weekend, I feel the duty to try and bring it back to life. I assume I'll be into it for a little less than a strip canoe since I'm actually starting with a canoe? right? Probably not. I have Mike Elliots "This Old Canoe" on order, so I'll have some reading to do this summer before I start anything. It will be interesting to find out where to start after I get the fiberglass off. I'm making a trip to Seattle in late October and I'll be looking for some Sitka Spruce for gunwales.

Mark

I drove over through Bozeman and met the fellow at his home and took a good look at the boat. As you'll see from the photos it needs lots of work. I think the fiberglass will come off easy enough, it already sounds like it's mostly separated from the wood. The inside is painted with latex, which will mostly come off with a fingernail. It has lots of broken or cracked ribs, perhaps 16, perhaps more? One inwale is in need of replacement (for some reason the other one is solid as a rock), as well as some amount of planking along the bottom of the boat. The rear seat is partially original as are the thwarts. The front seat is garbage. The decks have some rot near the tips and may be salvageable. I'm sure there's rot up under the stem tips, but looking under the decks it may not be excessive. The canoe is still pretty straight, which the fiberglass is surely responsible for. This boat probably would have gone to the dump long ago if it hadn't been glassed.

I paid the man the couple hundred dollars he was asking. At this point he said that if I actually do a restoration he'll give me the money back. I accepted his offer and added that we would go for a paddle in the canoe when I am done.

Here are some photos of its current condition. At least I can take it out for a paddle before I start to rip into it later this fall.

I really like the shape of the stems on this canoe.

This canoe was fiberglassed in the mid 1960's, and the fellow said the resin was setting as he was putting it on the boat. Hopefully that means an easier time for me getting it off. I think the glass and resin added a good 20 pounds to the boat.

The inwale and outwale on one side are shot. The canoe must have always been sitting on the ground on this side. The wood on the other side is in good shape. I'll try to find some spruce to replace the inwale.

The decks are in OK shape with a little rot near the tips. Hopefully I'll be able to save them. I'm not sure what those bolts were for.

Quite a number of broken or cracked ribs. A couple of the ribs have had these chunks replaced. The planking looks pretty bad on the bottom.

Original Build Record from Old Town. I think there's a lot more to find out about the history of this canoe from this document.

This is a 1931 photo of the camp where this canoe was delivered in 1928. All of these boats appear to be the same HW model as mine. My canoe may be in this photo.

This is the canoe in 1963. It still had canvas on it in this photo. The fiberglass was put on a few years later. When I picked up the boat, the fellow showed me the paddle he is holding in the stern.

Well, I seem to have quite a job ahead of me with this one. After finding all this history on the boat, and taking into account it turned 88 years old last weekend, I feel the duty to try and bring it back to life. I assume I'll be into it for a little less than a strip canoe since I'm actually starting with a canoe? right? Probably not. I have Mike Elliots "This Old Canoe" on order, so I'll have some reading to do this summer before I start anything. It will be interesting to find out where to start after I get the fiberglass off. I'm making a trip to Seattle in late October and I'll be looking for some Sitka Spruce for gunwales.

Mark