100 Miles & 37 Portages

I'll soon add more detail to this post for those that have graciously expressed interest in this old oddball (1994 MR Sunrunner). In short, the secret(s) to the success of this trip was a strong, 6'-5" farm boy and me being one heck of a camp cook to keep him/us fueled & spirits high. Also my Machiavellian way of shrugging off getting us lost on Nym and heading us into a moose swamp on portage #2 where my bowman promptly tore his new pants from ankle to crotch...And later using the same mind-tactic as I guided us into the entirely wrong lake being distracted by the quintessential canoe-tripping conversation...aliens...

More Later On...

I'll soon add more detail to this post for those that have graciously expressed interest in this old oddball (1994 MR Sunrunner). In short, the secret(s) to the success of this trip was a strong, 6'-5" farm boy and me being one heck of a camp cook to keep him/us fueled & spirits high. Also my Machiavellian way of shrugging off getting us lost on Nym and heading us into a moose swamp on portage #2 where my bowman promptly tore his new pants from ankle to crotch...And later using the same mind-tactic as I guided us into the entirely wrong lake being distracted by the quintessential canoe-tripping conversation...aliens...

More Later On...

- Gorilla Tape skid plates

- Ed's Canoe contoured seats

- Chosen Valley portage pads

- Handling in big water as well as twisty backwater

- Paddling efficiency vs portaging inefficiency

- Portaging 60' up (& down) 45 deg. slopes

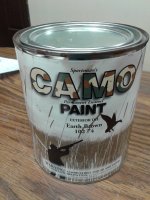

- Duck boat paint from Menards

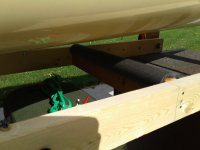

- Further developments of the "Canoe Rack Sling Thing"

- How the DIY roof rack performed on the Astro Van (754 miles)

- What a slug looks like having been mistakenly rolled up in a wet tent