Mark … I also built the woodstrip JEM North Wind plans, actually built two of them. I recommend you do your canoe weight calculations before committing to a layup. I built 2 because the first version came in over 70 lbs. The deck does add weight. First one was 1/4" cedar strips hull and deck, 6oz fiberglass inside and out hull and deck, a football of 6oz S-glass on hull bottom, plus S-glass skids, No fill coat on inside. Cockpit coaming 7/16" douglas fir with ash splints for the rim. Gun rack style seat bracket with Ed's extreme duty web seat. At my age it was a struggle to lift the boat after a paddle. So I use stern wheels to cart it up the boat launch.

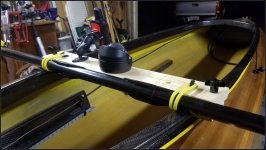

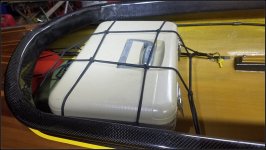

I sold the first one and immediately started 2nd version which came in at 61 lbs including rudder. Much better! I used variable thickness of cedar woodstrips, 1/4" below waterline, graduating to 3/16" on the deck, mostly from strips leftover from previous builds. Deck layup is 4oz fiberglass inside and out. The hull is still 1/4" cedar with 6oz E-glass plus football on outside, S-glass only for skids, and inner hull is 6oz E-glass in center and 4oz on ends starting about the end of cockpit. No inner fill coat. Cockpit coaming 3/8" mahogany with a carbon rim (which I molded from the 1st build). Same seat design as the 1st version. My rudder gudgeon is the one from Duckworks for pointed sterns which I had to bend the top piece to get the angle right, it is nice and solid. I added TruCourse rudder and foot controls which is good enough. The rudder, gudgeon and cables add 3 pounds but is worth it.

The canoe handles very fine and is plenty stable. It is an excellent design. But for my recent BWCAW solo trip I left this boat at home and instead took my Kevlar solo canoe which is 20 pounds lighter.

Larry

I sold the first one and immediately started 2nd version which came in at 61 lbs including rudder. Much better! I used variable thickness of cedar woodstrips, 1/4" below waterline, graduating to 3/16" on the deck, mostly from strips leftover from previous builds. Deck layup is 4oz fiberglass inside and out. The hull is still 1/4" cedar with 6oz E-glass plus football on outside, S-glass only for skids, and inner hull is 6oz E-glass in center and 4oz on ends starting about the end of cockpit. No inner fill coat. Cockpit coaming 3/8" mahogany with a carbon rim (which I molded from the 1st build). Same seat design as the 1st version. My rudder gudgeon is the one from Duckworks for pointed sterns which I had to bend the top piece to get the angle right, it is nice and solid. I added TruCourse rudder and foot controls which is good enough. The rudder, gudgeon and cables add 3 pounds but is worth it.

The canoe handles very fine and is plenty stable. It is an excellent design. But for my recent BWCAW solo trip I left this boat at home and instead took my Kevlar solo canoe which is 20 pounds lighter.

Larry