Well I've been gathering materials to start my Carbon Fiber Nokomis.

In the past, I relied on window heat shrink film as a release agent . Wrinkles were my biggest problem. As a release, it worked fine.

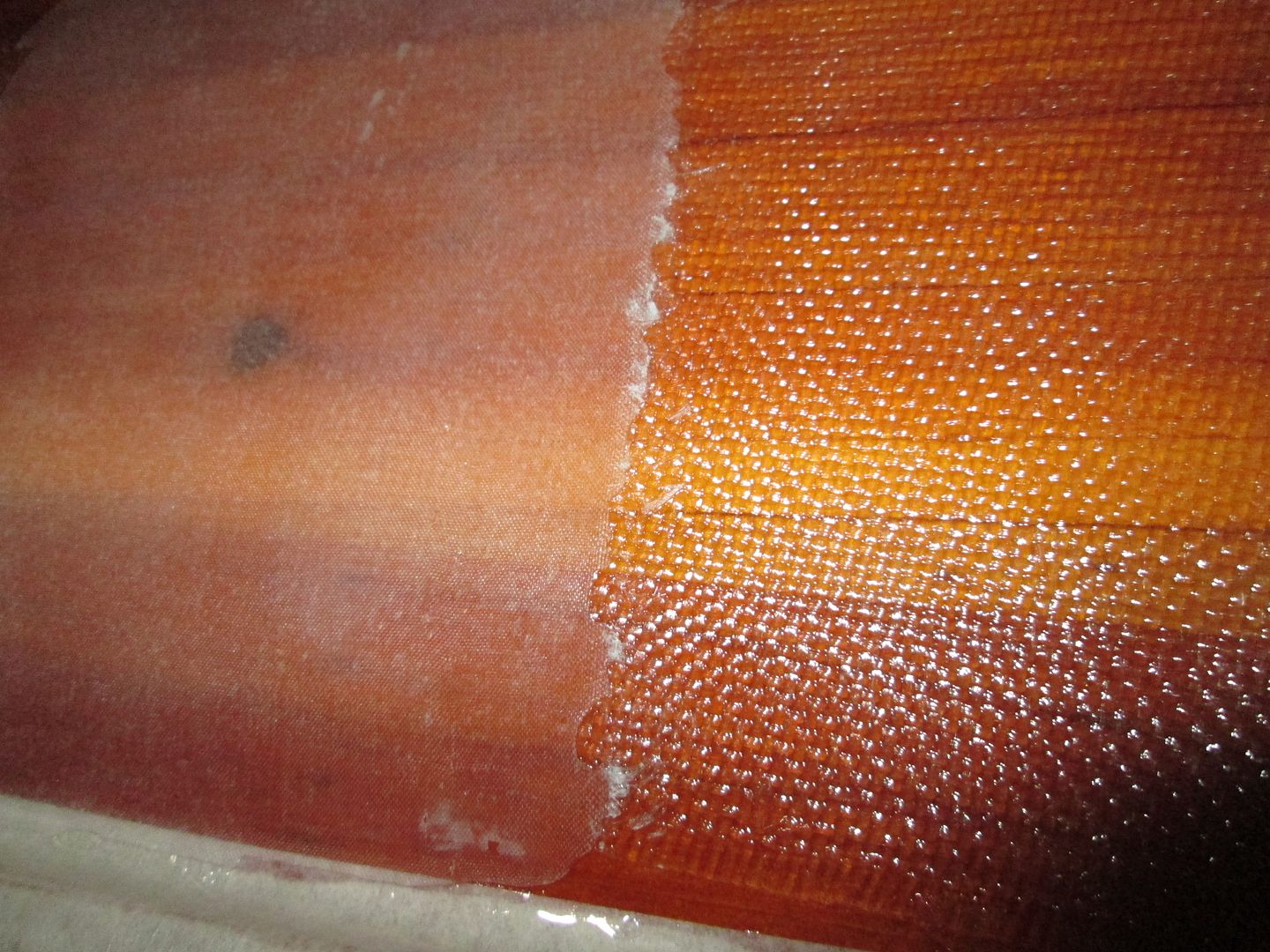

Well I'm trying PVA made by Partall, as my release agent.. The plan is to do some testing before I make the big jump.

I have two coatings of PVA brushed on a test piece.

I want to Thank Alan for steering me to a site, that had a lot of good info, dealing with fiberglass molding ! It was enlightening !

Resin is supposed to be here tomorrow, RAKA's UV-inhibited epoxy. I ordered a three gallon kit with half slow hardener, and half fast hardener.

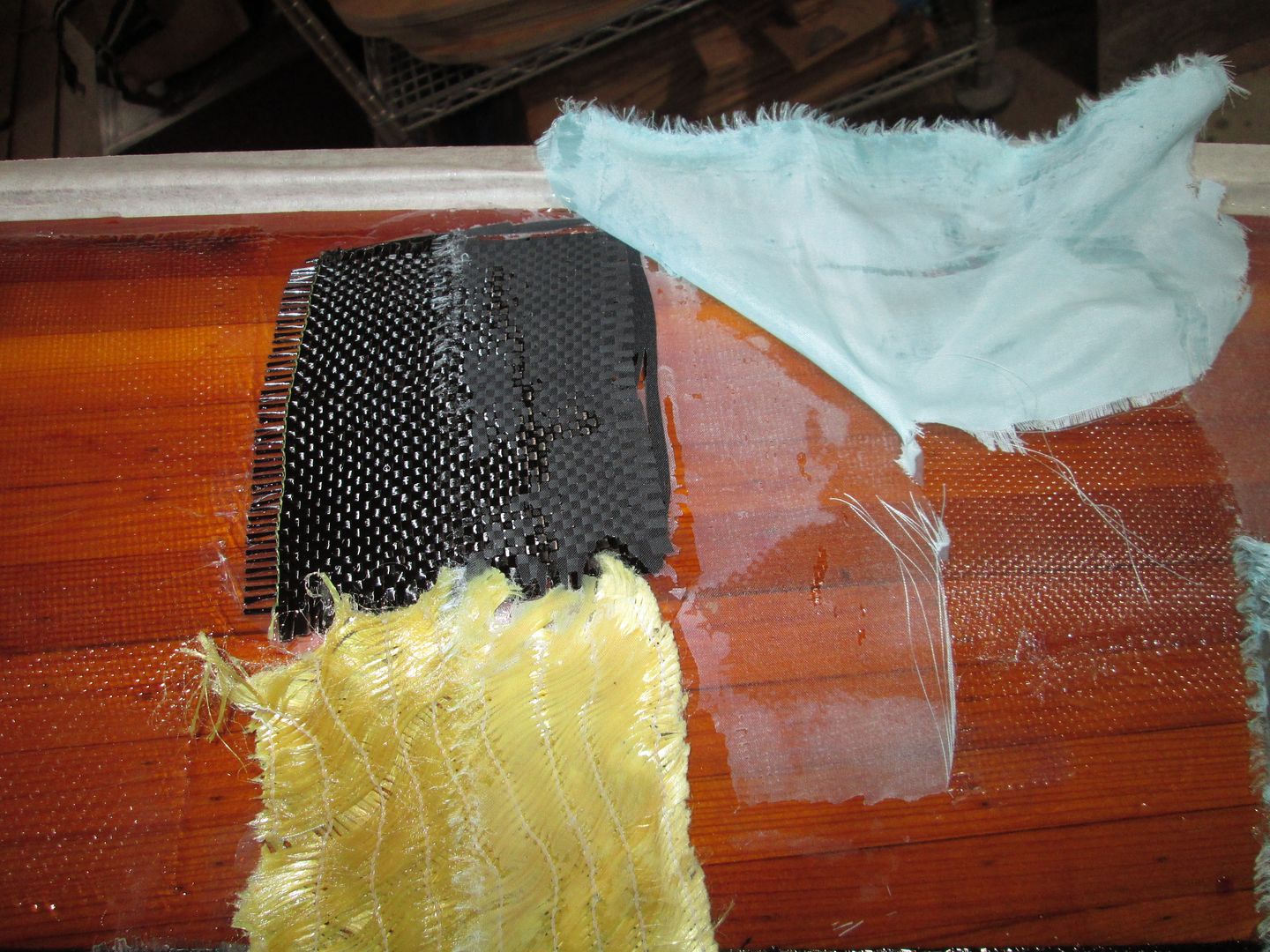

Going to test with several layers of scrap E-glass, and maybe some Kevlar, as well as some carbon fiber.

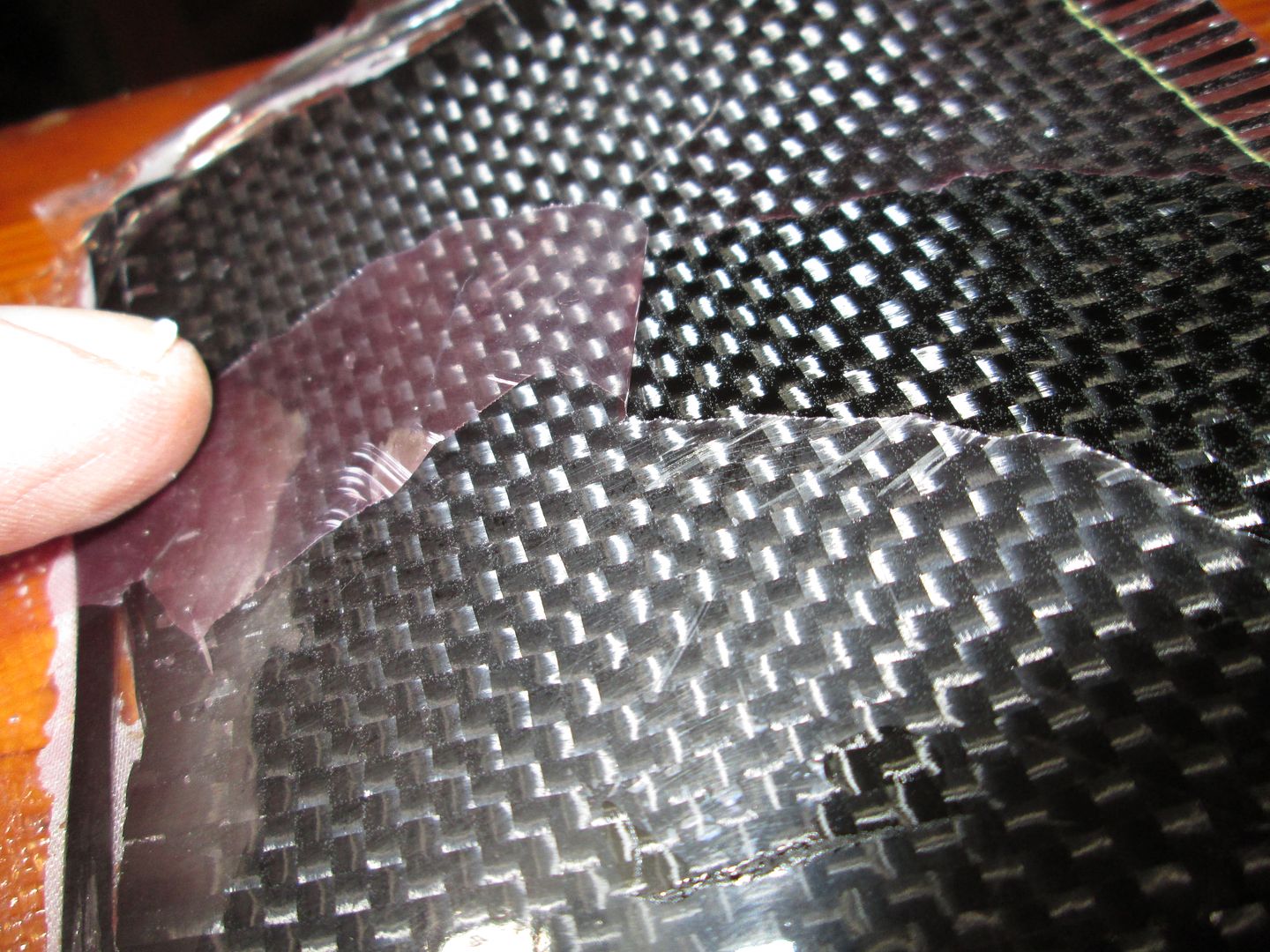

The object of the test is to tell me how long I can work the resin, how many layers,, I can easily wet out, and most important, how well the PVA works as a release.

Lastly how well the PVA will wash off the test hull.

These are all things I need to be sure of before I take the leap.

I'll keep posting.

Jim

In the past, I relied on window heat shrink film as a release agent . Wrinkles were my biggest problem. As a release, it worked fine.

Well I'm trying PVA made by Partall, as my release agent.. The plan is to do some testing before I make the big jump.

I have two coatings of PVA brushed on a test piece.

I want to Thank Alan for steering me to a site, that had a lot of good info, dealing with fiberglass molding ! It was enlightening !

Resin is supposed to be here tomorrow, RAKA's UV-inhibited epoxy. I ordered a three gallon kit with half slow hardener, and half fast hardener.

Going to test with several layers of scrap E-glass, and maybe some Kevlar, as well as some carbon fiber.

The object of the test is to tell me how long I can work the resin, how many layers,, I can easily wet out, and most important, how well the PVA works as a release.

Lastly how well the PVA will wash off the test hull.

These are all things I need to be sure of before I take the leap.

I'll keep posting.

Jim

Last edited: