Try too long and too much.

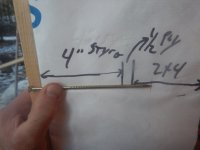

I and a friend "pulled wire" in a reno house this summer. The electrician was too busy to get it started, so we did. We were anxious to get boarding, taping, mudding...When the electrician did finally come to finish what we started he could barely stop from laughing. He called us "rich old guys", because we'd pulled so many single runs rather than series (a lot of wire) and left so much extra coiled at the new 100 amp box ( a lot of wire) he said he could've wired an extra house with all that we wasted. Oh well. We were feeling like pros until he said that. Ha. Legends in our own minds. He did really nice work, and he took the time to teach us a few things. Next time we'll slow down. And use way less wire. Or maybe just find something else to do until our electrician shows up. I blame this all on my friend. He's always in a hurry, and one of his favourite sayings is "How hard can it be?" My response is always the same " How hard can it be to f-up?"

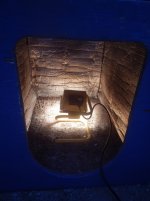

Nice looking shops guys. I like the standard beer bottle for comparison photo Canot. Good to have standards. Did you use that lamp to thaw the ground? Good idea. With no running water lines you'd need to ground somewhere. Must be tough to dig at this time of year up there. Com'on springtime!