Alan, you know what kind of hull you want to build, but I'm just going to use this post as a vehicle to voice a number of thoughts your comments and pictures evoke in me.

Much appreciated, Glenn. I'm always happy to hear the thoughts of experienced paddlers, especially ones who have different experiences (more whitewater) than me.

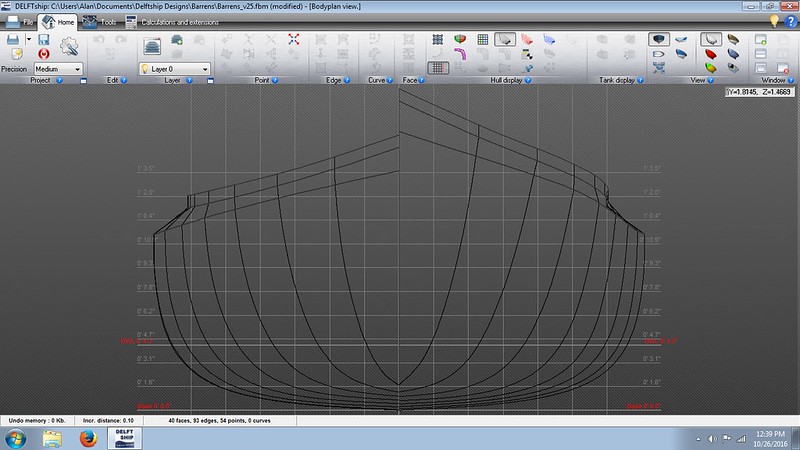

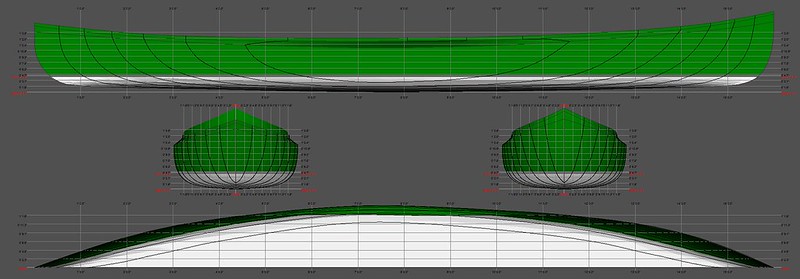

It's probably absurd to visualize the Barren from a couple of photos of forms, but it seems to have a flattish bottom, a fairly sharp chine amidships, and almost parallel sides extended further beyond the paddling station than is usual. I'd be very curious to test out the primary and secondary stability of the Barren.

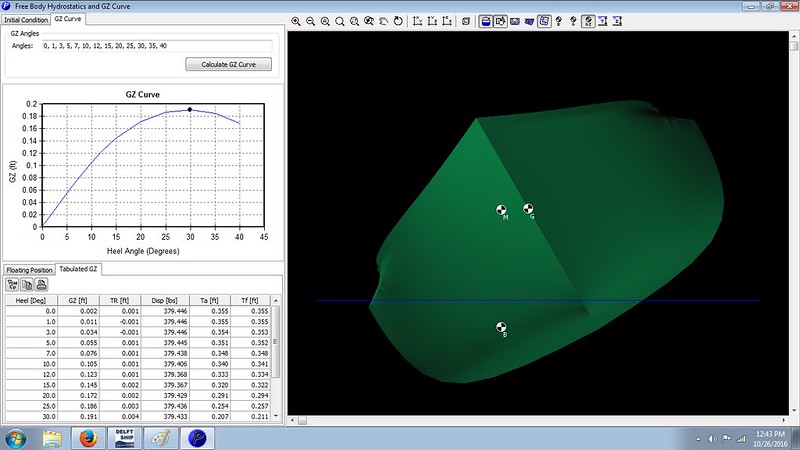

The bottom is flatter than many other more "advanced" designs, for lack of a better word. When I get a chance I'll upload a picture of the actual stations and that will make it easier to visualize. I can also upload the stability curve but that doesn't really do much good unless you have the same data on other hulls you've paddled. I don't mind a canoe that feels a little squirrely with the primary stability as long as it has firm secondary but in this case I opted to put more of the volume below the water line; the biggest reason being to float the canoe a little higher. I'm anticipating around 350 pounds of total weight and the more I rounded the hull, while keeping the max width at 32", the farther and farther it sunk into the water. So I tried to strike a balance somewhere in the middle. When comparing it to the other designs I've built this should have much more resistance to tipping at maximum heal (about 1 1/2" below the gunwale) but how the transition between flat keel and healed will feel I'm not yet able to determine by just looking at the graph. I suspect it will feel similar to the other hulls I've built and I'm ok with that.

In whitewater I strongly prefer a canoe with very progressive and finally solid secondary stability, so I can heel to the rail with absolute confidence.

No extreme healing for me, at least not intentionally. With a large load as well as a dog, neither of which are usually tied in place, I try to avoid healing the canoe too much as I'm always afraid of the dog or 70lb food barrel suddenly shifting and sending me the rest of the way over. I'll take a little extra primary stability for standing in the canoe to scout what's ahead.

I'm not sure what you mean by controlled vs. uncontrolled back ferrying.

I just meant that with my Bloodvein, which has differential rocker and a stickier stern, that I find it very difficult, with a fully loaded canoe, to keep the proper angle without the current pushing me around. I also get taken by surprise sometimes when I try to pass through a rapids slowly, in order to see what's coming and avoid obstacles, when suddenly I start getting pushed off line as the current catches my stern and essentially puts me in a back ferry.

I run into similar problems when lining. On more than one occasion the bow has been caught in the current and the only thing I can do is let go of the bow rope and let the canoe swing around while holding onto the stern rope. But now the sticky stern is facing upstream and I have to be

really careful to keep it from getting caught by the current until I can get a hand back on the canoe and the bow rope. I had this happen on my last trip and the stern did get caught in the current as I was trying to get back to the canoe. Fortunately I was close enough that once I was forced to let go of the stern rope I could grab the bow as it swung around but it made me realize how dangerous that sticky stern can be in some situations. Obviously the skill level of the person doing the lining comes into play here as well and I'll admit mine isn't very high. All the more reason to give myself any advantage I can.

In whitewater a canoe with more stern rocker will be easier to spin than one with lesser, and hence be easier to eddy and peel out. However, asymmetrically rockered canoes (such as my SRT) can easily be angled for a back ferry, but you may have to make the angle adjustment on the downstream side with a bow stroke (draw or pry).

Good point. That's something I'm working on making second nature but it's not there yet. When my stern starts getting manhandled in a fast rapid my instinct is to try and get it back in line by controlling the stern. Usually, by the time I realize what's going on, why it's going on, and what I really need to do, I've already made it through one way or another. Not having any local whitewater to practice on most of my learning comes while out tripping, where I'm less likely to take chances and get fancy. I should make an effort to hit some of the whitewater in N. Minnesota to get some practice in when the stakes aren't so high and I can try more things.

I think a lot of it comes down to the difference between a loaded and unloaded canoe. I have no doubt an experienced whitewater paddler can do a lot of things in a loaded tripping canoe I can't but there's a huge difference in the way the boats paddle loaded and empty. When empty I can back ferry, side slip, spin around and line up a set of rapids without much problem. But putting an extra 160 pounds into the boat sinks the hull farther in the water and turns it into a pig that doesn't want to do much of anything in a hurry. The boat I'm building now isn't something I'd want to paddle on flatwater with no load but, once loaded up for a 30-60 day trip, I'm hoping it will settle down nicely and give a good compromise between flat and moving water.

I love the under-stern rudder on my Huki outrigger canoe, and if I had any tools or skills I would think about making an under-stern rudder for a CanAm canoe. While my Huki rudder cannot be retracted while underway, I can remove it in 30 seconds by just pulling ashore for a minute and unscrewing one nut. It stays on the canoe almost always, and I just have to be a little more careful than usual about water depth. I did bend the shaft once when I smashed into an unseen boulder at high velocity on Lake Huron. The rudder cables for an under-stern rudder box wouldn't have to go outside the canoe or over the gunwales. I'm not sure whether that's an advantage or not.

They make a lot of sense for a 20' long boat that will be surfing swells but I don't know how much more effective they'd be on a tripping canoe.

I had an under-stern on my old WSBS Thunderbolt and while it worked very well I don't want one on a tripping canoe for a variety of reasons. On your Huki I'm assuming the rudder has a long shaft with a fastener on the top side you undo for removal? With an under-stern rudder it's necessary to have a waterproof housing that houses to rudder shaft that extends above the water line. Obviously you can't just drill a hole in the bottom of the canoe or water would rush in and you'd never be able to effectively seal it with o-rings. So on a tripping canoe you'd have a big box extending 8-10" above the floor, with cables running to the top of it, right where you'd want your packs to be.

I also worry about damage from impact with an under-stern rudder. The rudder on my Thunderbolt proved to be fairly robust but striking rocks in a 27 pound boat carrying only a 165 pound paddler is much different than striking rocks with a 50 pound boat carrying 300 pounds; especially in moving water. So to me a kick-up retractable rudder would be necessary for tripping.

Alan

20161023_001 by Alan, on Flickr

20161023_001 by Alan, on Flickr 20161023_002 by Alan, on Flickr

20161023_002 by Alan, on Flickr 20161023_001 by Alan, on Flickr

20161023_001 by Alan, on Flickr 20161023_002 by Alan, on Flickr

20161023_002 by Alan, on Flickr